Revolutionary small satellite launcher technology provides low-cost access to Space

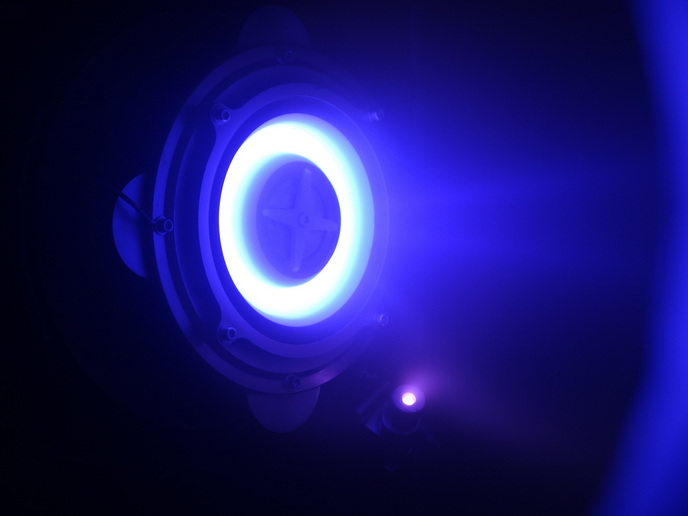

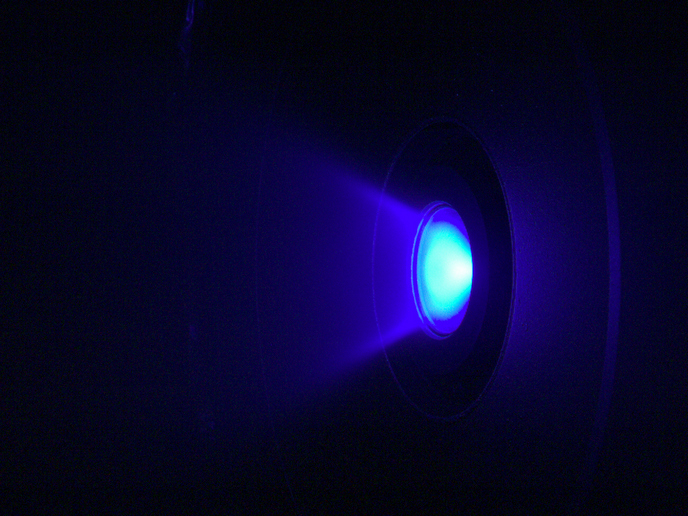

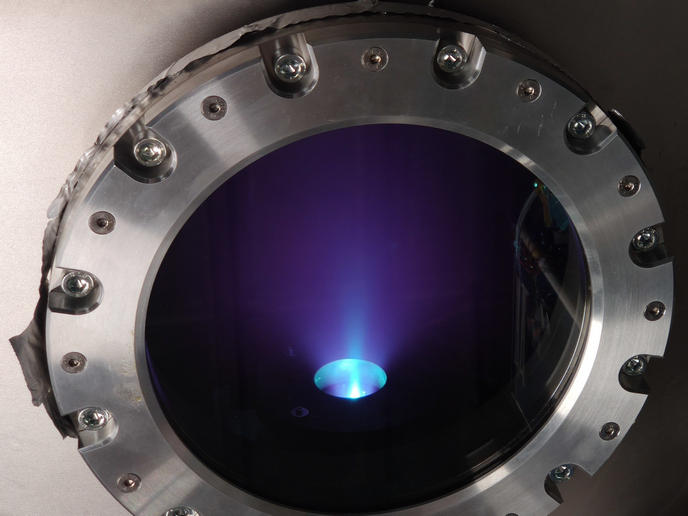

Owing to the advancements in satellite miniaturisation and electronics technology, the exploitation of Space assets for Earth observation, telecommunications, and Internet-connected objects is becoming more popular. These developments are bringing Space within reach of a wide range of private companies and it is no longer the preserve of a handful of governments with well-funded Space programmes. Microlaunchers – an alternative to small-satellite launch Traditionally, microsatellites are delivered as piggyback payloads on larger launch vehicles but long wait-periods and associated costs for launching is a serious issue. Companies have been offering rideshare services capable of shuttling several small satellites into space at once to drive down launch costs. Microlaunchers are an alternative to conventional rockets and are not new to satellite operators. Despite some progress in the field, developing robust and cost-effective microlaunchers has failed, owing to the relatively higher launch costs per payload kilogramme and immature technology. Acknowledging these challenges, the EU-funded Pangea Aerospace project laid the ground for developing reliable and affordable small-launch vehicles capable of delivering up to 150 kg of payload to low-Earth orbits. “Our main mission has been to develop new technologies for next-generation microlaunchers that lower the access cost to Space,” notes Luis Bellafont, chief financial officer at Barcelona-based startup Pangea Aerospace. Aerospike engines get a new lease on life How do Pangea Aerospace's technologies outperform the state of the art? Despite boasting several advantages over the traditional bell nozzle, aerospike nozzles have never flown, mainly because of technical difficulties and high costs of manufacturing. This status quo is changing thanks to Pangea Aerospace’s engine design approach, based on additive manufacturing technology. The aerospike engine that can adapt to the ambient pressure during the ascent increases efficiency by 15 % compared to the engine bell-shaped nozzles. Another aspect that makes this aerospike engine appealing is the use of 3D-printed components based on copper alloys. “Thanks to additive manufacturing, it is now possible to produce this type of engine. Furthermore, we need significantly fewer parts and process steps; these in turn reduce production costs and human error in the manufacturing,” notes Bellafont. Minimising the environmental impact of launches was a key consideration during rocket design. The engine of this compact, low-mass and low-carbon microlauncher runs on liquid methane and liquid oxygen; this propellant is clean burning compared to other fuels that are highly toxic and hypergolic. Reusable rockets – the catalyst for low-cost access to Space Pangea Aerospace has been rethinking the traditional rocket design process to include reusability of the launcher first stage from the very start. “Recovering the rocket first stage when most are designed to be single-use items saves costs from manufacturing new engines and minimises resources drastically. Engine design accounts more than 50 % of the total rocket production costs,” says Bellafont. The patent of the novel recovery and landing system for the first stage is pending. “Now that access to Space is being democratised and several private companies are entering the market, it is crucial to focus on developing as commercially viable technologies as possible. Several players may have entered the microlauncher market before Pangea Aerospace, but our innovative concepts for cost-effective microlauncher technologies will enable us to stay ahead of the curve,” concludes Bellafont.

Keywords

Pangea Aerospace, microlauncher, rocket, small satellites, first stage, low-Earth orbit, additive manufacturing, reusability