Ceramic additive manufacturing enters a new dimension

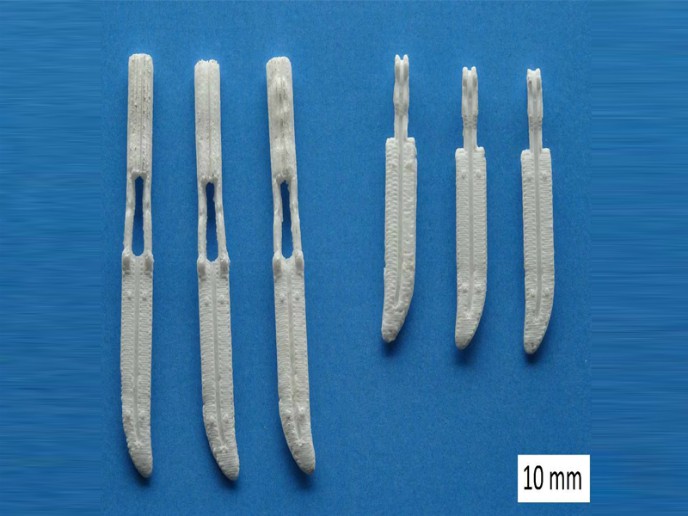

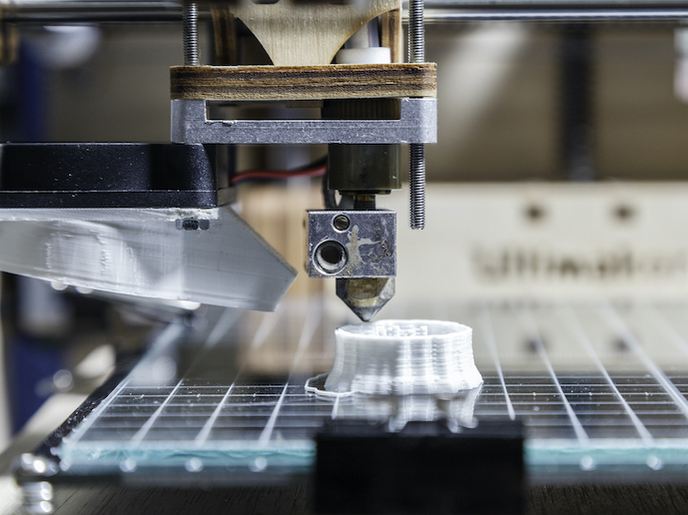

The EU-funded CerAMfacturing project has developed a completely new approach for ceramic multi-material AM. “Enabling series production of customised and multifunctional components for manifold applications, it’s possible to obtain property combinations that were previously incompatible like electrical conductive/electrical insulating, dense/porous or two-coloured components,” explains Dr Tassilo Moritz from the Fraunhofer Institute for Ceramic Technologies and Systems IKTS and project coordinator. Different production processes for a wide product range Researchers developed three tailored polymeric systems AM methods for manufacturing of multifunctional ceramic components: fused filament fabrication (FFF), thermoplastic 3D printing (T3DP), and lithography-based ceramic manufacturing, now known as vat photo polymerisation (VPP). All the processes have their specific uses and applications. With FFF, for example, it is possible to produce large and complex components quickly with high material efficiency. T3DP is particularly useful for a multi-material approach and applies suspension microdroplets for dot-wise manufacturing. VPP on the other hand uses layer-wise application of a light curable ceramic suspension that can be sintered to full density later. The CerAMfacturing team developed five very different case study components: an infrared (IR) heater, a spinal implant, a partial knee implant, a surgical micro-gripper and a customised watch case. Personalised and unique Initially, magnetic resonance spectrography data is transferred into CAD files to produce patient-specific medical implants such as knee or spinal implants, surgical grippers and therapeutic appliances. Based on customer anatomy and needs, the team selects the desired material or material combinations as well as the appropriate AM technology to produce the case study components. In addition, new ceramic or metal particle-filled filaments, suspensions and feedstocks were developed for different AM processes. All three newly developed AM machines for multi-material use for VPP, FFF and T3DP were successfully demonstrated at a project workshop in the second half of the project duration organised by Fraunhofer IKTS and at a workshop on Hybrid Materials and Additive Manufacturing Processes (HyMaPro) after project closure together with Fraunhofer IWS. Illustrating these three machines is the project video. Three separate films have been published in the Journal of Visualized Experiments (JoVE) recently. Solving the unexpected The originally planned IR limb heater proved to be too large for manufacture by the three AM routes and was substituted by a much smaller IR heater with an enclosed meandric heating structure. For another problem due to the incompatible thermal expansion coefficient of the initial material combination, a new partnership of stainless steel/zirconia was selected. The future for ceramic AM “Personalisation is high on the agenda,” points out Dr Moritz. “The CerAMfacturing project helped show a wider community the opportunities of AM techniques for individualising or customising medical and consumer products,” he continues. Individualisation of consumer products for a more sophisticated lifestyle is ‘trendy’, and the AM technique will safeguard such products from counterfeiting and bootlegging. Two patent applications have been filed based on the project results. For increasing awareness of the CerAMfacturing project results as a marketing tool, ‘CerAM’ in combination with the three developed AM methods will be registered as brand names: CerAM FFF, CerAM T3DP and CerAM VPP. “The project will act as a door opener for the hybridisation of materials and processes and will give a remarkable input to the scientific community on combining different materials by AM methods,” concludes Dr Moritz.

Keywords

CerAMfacturing, ceramic, AM methods, implant, additive manufacturing, surgical, multi-material, IR heater, fused filament fabrication, thermoplastic 3D printing, lithography-based ceramic manufacturing, vat photo polymerisation