New welding system builds storage tank market

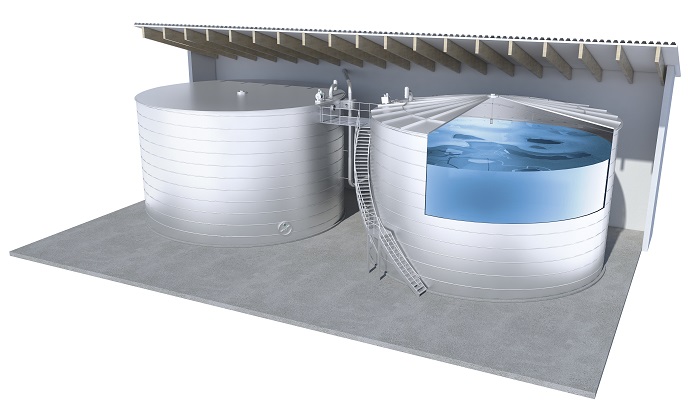

The EU-funded Horizon 2020 TechTanks (Revolutionary rib-welding system for the worldwide first fully automated production of large, high quality, on-site welded tanks, bringing considerable cost savings to drinking water applications) project used a revolutionary rib welding system for the first fully automated production of large, high-quality, on-site storage tanks. This approach, developed by German SME LIPP GmbH, ensures the highest levels of quality for storing solid, liquid and gaseous substances. The company applied its experience of double seam technology to create a ground-breaking automated rib welding system for the on-site erection of novel, flexible, large-scale, high-quality welded stainless steel tanks at low cost. The LIPP rib welding system can also be applied to conventional welded steel tanks, thereby opening the market for large oil and pharmaceutical/chemical tank applications, providing business opportunities in Europe and across the globe. Simple, fast and efficient According to project coordinator Manuel Lipp, the LIPP system is based on a simple yet ingenious method of tank construction that is the only one of its kind in the world. “The process is fast and efficient and conducted on site to build tanks of various heights and diameters,” he says. “They are built using an automated two-step procedure from steel strips. During the second step, the layers are joined together while the tank continues to grow upwards in a spiral.” Stability is ensured by tightly joining the steel strip using both the LIPP double seam system and the LIPP welding technique while ensuring stability. Computer data and video systems are used to remotely monitor the welding process. “Fitters watch the welding process from a safe distance in a control room. The necessary after-treatment of the weld is also automated, resulting in a weld that is extremely precise and smooth due to the automated continuous process,” explains Lipp. The speed of the manufacturing process almost doubled following the use of wider steel coils and by increasing the welding speed. Furthermore, the processing of thicker steel sheets is also being addressed. As a result, far larger tanks with diameters of more than 20 metres may soon be possible. Cost-effective solution creates new markets Marketing the revolutionary rib welding system was also central to the entire TechTanks project. “We promoted our welded tanks at regional and international trade fairs and visited many companies around the world to highlight the new LIPP welding process,” states Lipp. “Customer feedback was consistently positive, and we have implemented several pilot projects,” he adds. Significant material and manufacturing cost reductions of up to 45 % are possible due to the efficient, fast and automated on-site welding units. Cost reductions will lead to a unique selling position for applications in water and food industries, especially in drinking water storage. The water and food industries mainly use such types of tanks because of the strict hygiene regulations in this sector. Conservative estimations of the drinking water market show a yearly revenue of EUR 13 million in a EUR 1 billion market segment after successful introduction of the technology in the next five years. In addition, the LIPP rib welding system can be applied in the market of conventional welded steel tanks, creating a market for large oil and pharmaceutical/chemical tank applications. “This will strongly enhance our profitability and growth performance by transferring a substantially improved technology and existing knowledge into innovative, disruptive and competitive solutions, seizing European and global business opportunities,” Lipp concludes.

Keywords

TechTanks, steel, storage tank, rib-welding, drinking water, double seam system