Off-the-shelf heart valves

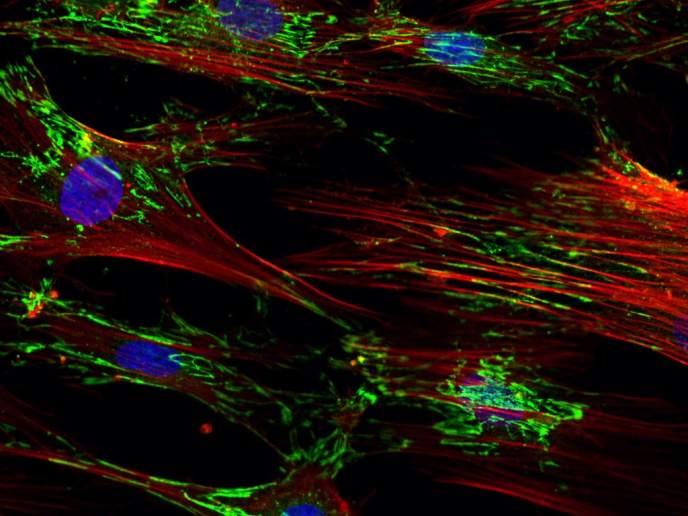

Current heart valve prostheses enhance survival and quality of life, but associated problems affect 30-35 % of the patients within 10 years after operation. This often translates into serious valve-related morbidity throughout life and a need for reoperation. Cardiovascular tissue engineering is rapidly moving towards in situ approaches where the implanted biomaterial induces regeneration directly in the functional site. The approach relies on the concept that the inflammatory response can be harnessed for tissue regeneration. The implanted biomaterial creates the proper microenvironment to support the interplay between immune cells, stem/progenitor cells and tissue cells, while over time it resorbs into a structure that can repair, remodel, and grow. Given the complexity of cardiovascular tissue, the challenge is to design a biomaterial with immunomodulatory properties capable of instructing new tissue formation. The EU-funded IMAVALVE project proposed to address this issue by developing intelligent materials that can transform into a novel synthetic heart valve. Delivery of the novel valve occurs through a minimally invasive trans-catheter procedure, eliminating the need for open heart surgery. “The idea was to generate a biomaterial that can gradually transform into a living, durable aortic heart inside a patient’s body,″ explains the project manager Laurens Schrijnemakers. New intelligent materials During the project, researchers designed and characterised a number of polymer materials as well as hydrated gel-like materials. The objective was to combine a relatively slow-degrading elastomeric material with a fast-degrading bioactive hydrogel material. The former ensures long-term functionality of the valve and supports mature tissue formation, while the hydrogel material controls the early inflammatory response. The chosen materials offered a number of advantages including biocompatibility and tunability with respect to elasticity, stiffness and strength. Considerable effort went also towards developing a mechanistic understanding of the human host response to the biomaterial. Researchers tested in particular, the effect of selected bioactive molecules on the host response and subsequent early tissue formation. They incorporated peptides that can recruit the patient’s macrophages and stimulate them towards the tissue-forming fate. Additionally, the consortium incorporated insight into cardiovascular cell signalling in response to mechanical cues in a computational model and used it to predict the growth and remodelling of the heart valve. Using this model, they found mechanical strain to be a prime factor in valve growth and remodelling with age. Furthermore, computational simulations of tissue engineered heart valves enabled scientists to predict the in vivo performance of the implanted structures. Towards more efficient valve replacement Using a catheter delivery system developed during the project, the consortium performed a proof-of-concept in vivo study to assess intra-operative handling and valve deployment. Although clinical studies are pending, Dr Schrijnemakers envisages: “the consortium has to perform an extended range of in vitro and preclinical studies to test the safety and durability of the valve under a wide range of conditions.″ Considering that valve replacement is a common intervention, with over 300 000 annual replacements worldwide, the IMAVALVE technology will offer a significant alternative to existing approaches. Its capacity to grow and adjust to cardiac functional demands overcomes the limitations associated with current prosthetic valves and is suitable for young patients as well. Importantly, the ease of implantation constitutes a significant advantage as it bypasses the need for surgery, improving patient quality of life and reducing healthcare costs.

Keywords

IMAVALVE, heart valve, biomaterial, tissue engineering, polymer