New printing techniques bring ‘lab-on-paper’ within reach

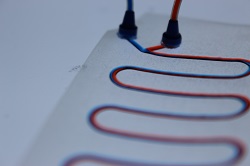

EU researchers have made progress on techniques which could soon allow us to have disposable paper-based diagnostic devices that can do everything we can currently do in a lab but much faster and at a fraction of the cost. NANOPAD has come up with ways of printing using electrical inks to turn plain paper into sophisticated electrochemical devices. The three-year project, funded as a Marie Curie fellowship, took Swedish materials scientist Max Hamedi to the United States to develop his ideas in the labs at Harvard University. Scientists have been trying to unify biochemistry, electronics and microfluidics or the handling of liquids to build micro total analysis systems for many years. Dr. Hamedi is confident that his team’s approach — using smart conductive inks to print on paper and other materials — marks a significant step forward. The technique involves micropatterning porous electronic conductors on paper. Unlike conventional printed wires, these are porous with a high surface area, can carry liquids and electrons simultaneously and can withstand scratches or creasing of the paper. The results of NANOPAD include integrating ion sensors into paper, developing the first printed electrical valve that can control the flow of liquids and showing it is possible to electronically control liquids by printing on textiles. “Another significant finding is that … you can coat the surfaces of cellulose so that it acts like conductive e-paper,” says Dr Hamedi, now assistant professor of chemistry at KTH Royal Institute of Technology in Stockholm, Sweden. This means a piece of paper could soak up a liquid, such as blood for testing, produce a biochemical reaction, “and then you can read the signals electronically,” he adds. Diagnostics for everyone These advances could help democratise our access to sensors and, through this, to advanced diagnostics for disease and easy monitoring of health markers. This would revolutionise how patients in hospitals are diagnosed but it is at point of care in more difficult conditions, such as when doctors provide healthcare in rural areas or developing countries, where it could really make a difference. “Imagine I say that I have a device you can plug into your phone and it would detect which strain of malaria you are dealing with,” says Dr Hamedi by way of illustration. Integration means innovation Monitoring the environment is a second area where Dr Hamedi believes it could have a big impact, although he readily admits that it is hard to predict what uses such devices could be put to in future. “Materials science is not always about coming up with new materials, it is about thinking about existing ones in new ways,” he says. “Paper has been used for 50 years or more as a platform for making some kind of sensing device but the real innovation is to integrate how you control liquids and how you digitalise the data.” Seven articles have been published on the results and Harvard University has applied for five patents covering the technology. Back in Stockholm since 2016 Dr Hamedi is now running his own research group focusing on applying printing technology to DNA.

Keywords

NANOPAD, diagnostics, microTAS, miniaturised systems, electronic inks, biosensing, electrochemcial devices