Reaching a better understanding of molecular self-assembly in organic solar cells

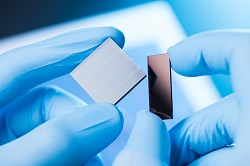

Organic solar cells offer the prospect of not only a cheaper alternative to the dominant silicon variety, but also increased flexibility of application. Owing to their thinness, they could be used across larger surface areas and could be applied directly to building materials of varying shapes, unlike conventional polymer solar cells (PSCs) which are limited to flat surfaces. However, working out the relative merits of organic semiconductor coatings presents an experimental challenge to researchers, partly due to the thinness of their layers, rendering performance effects subtle and so hard to measure. The EU-funded NEUTRONOPV took up this challenge at a general level to develop a better understanding of the relationship between processing conditions, active layer morphology and device performance in solar cells. They also specifically sought to develop new and more exacting characterisation techniques, for the study of solar cells. Neutrons and the nanostructure In order to gain a systematic understanding of how subtle changes in solar cell film composition resulted in changes to cell efficiency, the NEUTRONOPV project processed a variety of semiconducting polymers mixtures. The researchers then took these step-graded variations in composition to generate a series of devices with different morphologies, which could then be measured against criteria such as charge mobility and photovoltaic performance. These very thin (less than one micron) films were created both by the laboratory-based spin-coating method and also the industrially-scalable method of spray-coating. As Professor Richard Jones further explains, ‘The process by which we make these is very simple – just like painting a varnish on a surface – but what goes on during that process – what the molecules are doing – is very complicated. They arrange themselves to form particular nanoscale structures, and it’s the nature of that structure that determines how efficient the solar cell is.’ In order to better understand the self-assembly of the molecules, the team used techniques which directs a beam of neutrons at the sample and then measures how these neutrons were scattered by the nanoscale structures present in the layer. As Professor Jones elucidates, ‘While this approach is much more powerful than other techniques, in that it gives us quantitative results representative of the whole of the film, it is difficult to do on very thin films as the effect individually on the neutron beam is very weak.’ To overcome this challenge, the project’s Research Fellow Gabriel Bernado devised a method of stacking a large number of films together to multiply the effect. The neutron-based approaches were also complemented with more conventional laboratory-based techniques. Towards the low carbon economy There are seen to be multiple benefits to this mixed composition approach. It offers the prospect of a more sustainable production, for example by offering substitutes for halogenated solvents, which have been demonstrated to be hazardous to human health as well as the environment. Additionally, as organic solar cells promise to be cheaper, easier to apply to large areas and much more adaptable to varying surfaces, than traditional silicon options, they are likely to be readily adopted, thus supporting efforts to build a low carbon economy. As Professor Jones enthuses, ‘I’m passionate about the potential that self-assembly – where molecules arrange themselves, following simple rules, to form complex structures – offers for functional devices that do interesting and useful things, like convert light to electricity. I want to understand how those processes work, so we can exploit them to the benefit of society.’ Towards this end the team are now working to apply these techniques and methodologies to a variety of different systems, including hybrids of organic semiconductors and inorganic semiconductor nanoparticles.

Keywords

organic photovoltaic, neutron, nanoscale structure, solar cells, low carbon economy, semiconductor coatings, spin-coating, spray-coating, self-assembly