Piezoelectric energy harvesting scaled down

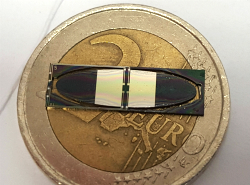

Energy harvesting at low frequencies was difficult in the past due to the brittle nature of materials from which harvesters are made. In particular, the limited stiffness of conventional silicon and all piezoelectric materials hindered the development of vibration harvesting systems that operate below 100 Hz. This lack of durable energy harvesting systems in the low-frequency range was the focus of MANPOWER (Energy harvesting and storage for low frequency vibrations). 'The main objectives were the development of materials and electronic structures for the two core components of a low-frequency energy harvester: the energy harvester and the charge storage device', noted Dr Cian Ó Murchú coordinator of the EU-funded project. The targeted vibration frequency range was from 20 to 30 Hz. To this end, nanotechnologists, and communications technology experts worked together with physicists to develop a technology that harnesses the energy of heart vibrations. MANPOWER partners developed self-oscillating polymeric substrates and optimized piezoelectric materials that can be used at the scale needed. A vibrating cantilever, which was created out of these materials, responds to the motion of a beating human heart. Although the technology was already available at larger scales for mechanical and industrial use, the next step of their work was to adapt this for use in a self-powered pacemaker. The size constraints were one of the main challenges to overcome during MANPOWER. 'As the size of the energy harvester shrinks, the power that can be generated is also reduced. The initial power requirements for the pacemaker were considerably higher than that achievable by the tiny energy harvester. However, we were able to meet the specification provided with a combination of design and material optimisation together with improved circuitry', explained Dr Ó Murchú. An implantable device also required biocompatible packaging technologies to integrate the full system and theoretical modelling to assess components' reliability and project their lifetime. Before the project's end, the prototype pacemaker package including a three-axis accelerometer was implanted into a sheep's heart for in vivo testing. The results promise a better life for heart patients. Pacemakers that rely on vibrational energy harvesters are small enough to be implanted into the heart wall and can function for a much longer period than conventional pacemakers' batteries. According to Dr Ó Murchú, the 'MANPOWER energy harvester can be applied to other sources of low-frequency vibration, such as human motion, vehicle engines, ship motion and waves.'

Keywords

Energy harvesting, pacemakers, piezoelectric materials, MANPOWER, low frequency vibrations