Intelligent tools to ramp up production in the manufacturing industry

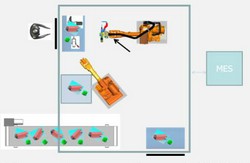

Existing ramp-up practices for products and services take up considerable time and energy, mainly because they are carried out manually. This is not feasible for a manufacturing SME that needs several or even repeated product modifications. With this in mind, the EU-funded I-RAMP3 (Intelligent reconfigurable machines for smart plug & produce production) project set out to develop a smart and flexible system that reduces the intervals for production lines and associated costs. To achieve this, project partners incorporated added capabilities into current and new production networks. They converted conventional production equipment into ‘Network-enabled devices’ (NETDEVs). These production devices are equipped with built-in intelligence by integrating a communication framework and models for various capabilities such as self-description and self-configuration. With such capabilities, enormous time and effort reductions are enabled, leading to faster ramp-up and optimised process implementation, maintenance and quality. Work began by devising a communication framework for heterogeneous devices with varying capabilities. The aim was to find an optimal device setup during ramp-up for three typical manufacturing scenarios: Initial ramp-up, Ramp-up after component/product exchange and Ramp-up after maintenance. I-RAMP3 developed plug-and-produce devices for fast ramp-up and flexible production based on I-RAMP3 technology. This was achieved by creating and validating a model for NETDEV components of different characteristics and functionality as well as their interfacing. Furthermore, an interfacing of the NETDEV technology with ‘Manufacturing execution systems’ (MES) and ‘Enterprise resource planning’ (ERP) systems was implemented. Project partners also developed intelligent sensors and actuators with built-in intelligence for fast exchange of components. A hardware and software platform for the autonomous sensors was set up. The components were then integrated into the I-RAMP3 NETDEV technology. In addition, they developed an integrated, intelligent workflow system and associated components for fast ramp-up and flexible production. The developed components were integrated in three demonstrators, each demonstrating one of the three ramp-up scenarios as mentioned above. Specifically, the demonstrators illustrated the following: Initial ramp-up (Set-up & ramp-up of a new E-Vehicle assembly line), Ramp-up after component/product exchange (Component exchange in E-Vehicle subassembly unit) and Ramp-up after maintenance (Enhancing devices with re-use & predictive maintenance capabilities). I-RAMP3 will boost the competitive advantage of manufacturing SMEs via tools that reduce production costs and increase manufacturing efficiency. This novel technology based on communicating, self-descriptive and self-configuring smart components should bring the European manufacturing industry one step closer to the vision of flexible, adaptive and sustainable production of the intelligent factory of the future.

Keywords

Production, manufacturing SMEs, ramp-up, I-RAMP3, network-enabled devices