Better surgical tools for fewer infections

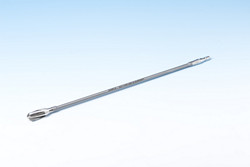

Bone reamers are used to form or enlarge holes in bone prior to insertion of prostheses. They are made of stainless steel cutting heads and shape memory alloy (SMA) flexible shafts. Mechanical coupling creates crevices that are difficult to clean and sterilise, increasing the risk of infection and, increasingly, of antibiotic-resistant infection. Welding could eliminate the crevices and contamination but the properties of stainless steel and SMAs are severely degraded when melted. To solve the problem, scientists launched the EU-funded project CLEANTOOLS. The team is exploiting rotary friction welding (RFW), a novel solid-state process that softens materials with friction heat and coalesces them with compressive force. Utilisation of RFW will require careful consideration of the materials for biocompatibility, service requirements and weld properties. In addition to legislative and literature reviews, researchers conducted experimental tests pointing to the need for an interlayer between the SMA and the stainless steel. Numerous weld trials have been conducted with the selected materials to optimise weld parameters to achieve required joint strength and ductility. Having demonstrated consistent tensile and guided bend test results, the team is now investigating commercialisation opportunities for this novel technology. CLEANTOOLS is on its way to delivering a method for producing surgical instruments with enhanced function and ease of cleaning. Exploitation of RFW will improve reliability, decrease manufacturing costs and reduce patient infections for major benefits across the board.

Keywords

Surgical tools, infections, orthopaedic, orthopaedic surgery, welding, sterilisation, stainless steel, shape memory alloy, rotary friction welding, biocompatibility, interlayer materials