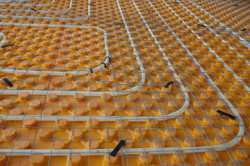

Recyclable plastic heating pipes

The EU-funded NANOFLEX project developed plastic pipes for the construction industry that comply with EU directives concerning landfill and waste management. It created a universal, flexible and low-cost plumbing and heating system for both hot and cold water systems, including underfloor heat and the distribution of drinking water. Conventional non-recyclable pipes for heating and plumbing systems are manufactured from non-recyclable cross-linked polyethylene (PEX). They are also made of PEX/AL, which comprises a layer of aluminium sandwiched between two PEX layers. The pipes have inner and outer layers to prevent corrosion and scaling and a centre layer that provides a necessary oxygen barrier layer. Researchers developed a thermoplastic pipe without PEX and without bonding of layers and with no aluminium layer in order for the pipe to be 100 % recyclable. This was achieved by replacing the aluminium or expensive oxygen barrier materials with innovative nanocomposites together with a redefined wrapping technology. The project partners developed nanoparticle compounds of montmorillonite clay for use with low-cost thermoplastic pipes. A process was also developed that enables the extrusion of the inner pipe and its wrapping with previously developed nanoparticle-coated tape. In addition, the team advanced a process for coating the outer layer and a surface treatment for improving slip properties and reducing noise impact. NANOFLEX technology provides a number of benefits for pipe manufacturers and distributors, beginning with the economic gains of selling a new, fully recyclable pipe system. Indirect economic benefits include avoiding financial penalties for using non-recyclable plastics, faster installation times and water cost savings.

Keywords

Recyclable, underfloor heating, plumbing, thermoplastic, nanocomposite, montmorillonite, waste management