Multiscale models of nanocomposites

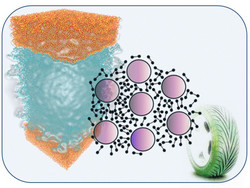

Nanofilled polymer matrix composites are replacing conventional polymers in many industries because they can offer tailor-made functionality. A consortium of Russian and European research groups developed simulation software to speed development with EU funding of the COMPNANOCOMP (Multiscale computational approach to the design of polymer-matrix nanocomposites) project. Scientists developed and validated the methodology and software against two main categories of systems, soft silica-filled natural and synthetic rubbers (thermoplastic elastomers) and carbon nanotube (CNT)-filled thermoset resins. To understand the effects of reinforcement of polymer-matrix nanocomposites by filler particles, the team integrated three interconnected levels of representation with a special focus on silica‐filled natural-rubber 'green tyre' materials. The first level was a detailed atomistic representation of both polymer chains and nanoparticles. Their behaviour was tracked with molecular dynamics. The intermediate scale modelled the polymers as freely-jointed chains and the nanoparticles as single spheres using Field Theory-inspired Monte Carlo. The coarsest level represented the polymer in terms of chain ends, crosslink, entanglement, adsorption and grafting points using coarse-grained Brownian dynamics coupled with kinetic Monte Carlo simulations. They also developed a method to estimate the rates of adsorption and desorption of end-constrained chains (by cross-links or entanglements) from a polymer melt onto a solid substrate for use in the coarse representation. Another approach modelled elastic and dissipative properties of reinforced elastomers. Comparisons to experimental data showed very good qualitative agreement. A multiscale strategy, which combines on-the-fly mapping/reverse mapping schemes, the network building procedure based on reactive dissipative particle dynamics and the fully atomistic molecular dynamics, was used to simulate highly cross-linked epoxy resins filled with both single-wall and multiwall CNTs. These simulations elucidated important properties of the CNT-epoxy systems as well as their relationships to processing parameters. Through simulation work supported by experimental optimisation, the team produced nanofilled matrices, using CNTs for aerospace applications and silica for wind energy applications. They enhanced the performance of carbon fibre-reinforced composites. COMPNANOCOMP multiscale models of nanofilled thermoplastic and thermoset polymers promise to speed development of high-performance tailored nanocomposites for many industries including transport and energy. Training workshops and research exchanges organised to impart knowledge about the software to students and researchers will enhance uptake and maximise impact.

Keywords

Multiscale, nanocomposite, polymer, simulation, nanofilled, elastomer, CNT