Advanced marine turbine holds potential for mass uptake

The escalating threats of climate change and geopolitical tensions emphasise the urgent need to develop renewable energy technology and expand capacity. Marine energy, particularly wave and tidal resources, is crucial in this endeavour, with plans to reach 100 GW of production capacity by 2050. This effort is vital for transforming the EU’s energy system from reliance on imported fossil fuels to a flexible and interconnected network of clean, renewable and indigenous resources. Contributing to this transition, the EU-funded CRIMSON project offered a low-risk approach to harness marine energy’s untapped potential, paving the way for sustainable domestic energy solutions. “We produced a new, cost-effective marine energy system that is reliable and built with sustainability in mind. By using recycled materials and planning for the cradle-to-grave life cycle of the system, the technology seeks to replace fossil fuel energy with clean energy from tidal currents,” notes project coordinator Tomas Flanagan. “In the long run, this technology has the potential to produce gigawatt amounts of energy from tidal currents.”

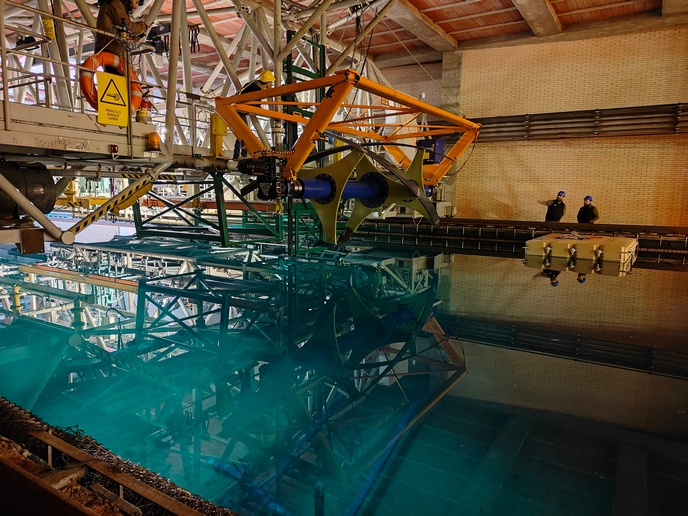

Rigorous testing propelling marine energy technology forward

CRIMSON’s target was to spread the use of marine hydrokinetic power systems across Europe, focusing on making them more accessible. It sought to enhance the use of recycled carbon fibre by evaluating its durability through mechanical tests and assessing its environmental impact. This turbine also featured a structural health monitoring system and a modular design to produce reliable, predictable renewable energy. Structural testing and operational trials were also conducted to confirm the turbine’s strength and reliability. “Our structural testing programme was designed to adhere to stringent test specifications, covering various tests like dynamic, static and fatigue tests, as well as a destructive test to assess residual strength,” outlines Flanagan. “A notable achievement was completing 1 300 000 fatigue cycles – the highest number of cycles ever recorded for a tidal turbine blade under dry laboratory conditions. We also demonstrated that the foil could handle 115 % of the maximum expected load.” Full-scale operational tests were conducted in Rome’s large towing tank, with over 220 runs, examining the turbine performance under different conditions. These tests demonstrated potential reductions in both capital and operational costs for a turbine capable of generating up to 2 MW of power.

Testing durability of recycled carbon fibre

Testing activities allowed project partners to benchmark the recycled carbon fibre with commonly used materials in marine energy. It assessed how recycled carbon fibre performs in harsh marine environments and provided data on its merits and limitations. The trials generated valuable data on the turbine’s electrical and mechanical performance and identified failure modes in the composite material, aiding optimisation efforts in future designs. The accuracy of an advanced fibre Bragg grating strain measurement system was also confirmed, showing its potential for monitoring structural health during turbine operation.

Bright prospects for sustainable energy production

“CRIMSON perfectly aligns with the Sustainable Development Goal 7 – focusing on cleaner and more efficient energy production – while also embracing circular economy principles and integrated supply chains,” highlights Flanagan. “It successfully demonstrated the use of recycled carbon fibre in marine renewable energy systems. A project partner has been the first to implement these new technologies in their TidGen and RivGen power systems, showcasing CRIMSON’s achievements in sustainable energy advancements.” Efforts are underway to further lower the cost of energy production, aiming to reach EUR 150 per kWh by 2025, aligning with the SET Plan targets for ocean energy.

Keywords

CRIMSON, recycled carbon fibre, marine turbine, hydrokinetic energy, renewable energy