The future of electric cars is light-weight and recyclable

Reaching carbon neutrality by 2050 cannot be achieved without advances in road transport, which is responsible for 76 % of transportation emissions in Europe. Battery-operated electric vehicles (BEV) are key to this transformation, and the efficiency of such cars hinges on their weight. In addition, legislative initiatives necessitate embedding circularity into the design of new vehicles, further raising the bar for BEV innovation. With a market-facing consortium of nine partners from Germany, Spain, France and the Netherlands, the EU-funded ALMA project delivers on both of these objectives.

A multi-material modular platform

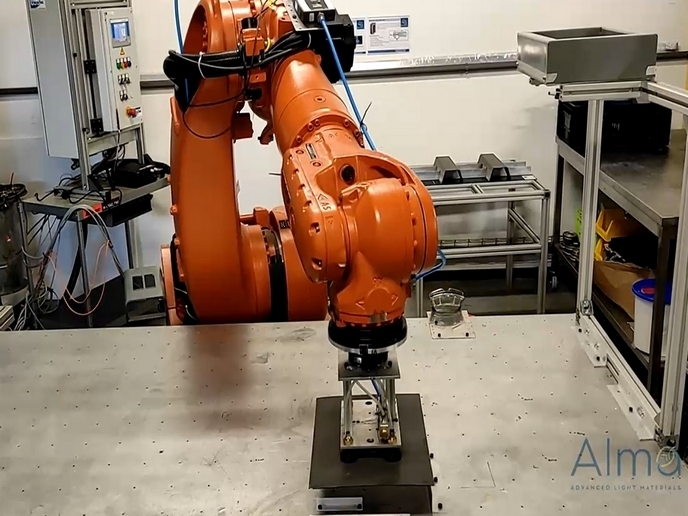

According to project coordinator Raquel Ledo Bañobre: “The main goal of ALMA was the development of a novel electric vehicle structure for a passenger car with reduced weight and environmental impact, thanks to the adoption of an integrated eco-design and circular approach across the entire life cycle of the vehicle.” Achieving this goal required a multi-faceted approach and the expertise of several project partners. The project worked with advanced high-strength steels, advanced sheet moulding compounds and steel hybrid materials to manufacture lightweight components of BEV passenger cars. The body-in-white of Alma’s concept car achieved a 160 kg weight reduction compared to the baseline, leading to a 22 % decrease in weight. Using laser welded blanks technology, ALMA was able to consolidate multiple car parts into a single lightweight component. This process reduced cost, weight and emissions of the vehicle. It also improved performance and safety by ensuring that the right material was in the right place. Because end-of-life legislation requires higher levels of vehicle recycling, ALMA also developed separation technologies to break down the consolidated components. Key separation technologies rely on heat-triggered debonding primers, and the project investigated several promising processes, including pyrolysis and solvolysis.

Digital tools steer design

Since up 80 % of a vehicle’s environmental impact is determined at the design stage, ALMA’s focus on eco-friendly design is the foundation of the project’s achievements. Digital tools were instrumental in prioritising safety, efficiency and circularity in the vehicle prototype. Life cycle assessment (LCA) and life cycle cost analysis (LCC) were at the forefront of the project. To complete these assessments, ALMA developed the battery electric vehicle sustainability impact assessment model (BEVSIM). Bañobre says: “This tool enables users to measure and compare impacts resulting from design alternatives, material choices, recycling technologies, end-of-life scenarios, and future scenarios due to changes in grid mixes.” Project partners also developed a structural monitoring system using acoustic signature analysis to determine the condition of components. Alerts regarding potential damage improve safety and enable decisions that impact the repair, reuse or recycling of vehicle components. Several of ALMA’s achievements are market-ready. BEVSIM makes LCA and LCC more accessible to automotive engineers, leading to better vehicle design. Innovative advanced materials and debonding technologies are also ready for market uptake. To achieve the transformation of the BEV industry, Bañobre shares: “A full scale-up and industrialisation study still needs to be put in place, including the need for manufacturing of new tools and moulds to enable reaching the high production volume and cycle times required in the automotive industry.” Due to the work of ALMA and other industry stakeholders, an eco-friendly transformation of road transport is close at hand.

Keywords

ALMA, eco-design, recyclable, BEVSIM, acoustic signature analysis, electric cars, energy-efficient, light-weight materials, laser welded banks technology