Cost-competitive floating offshore wind energy is on the horizon

Wind is the second largest electricity generator in the renewables family next to hydropower and it produces more than all the others combined. Offshore wind provided less than 1 % of global power generation in 2019, but it is poised to play an outsized role in the clean energy transition. The EU-funded COREWIND project set out to reduce costs, the key challenge to realising this potential. Reductions were addressed throughout the life cycle by optimising wind farm layout, component design, installation, operation and maintenance.

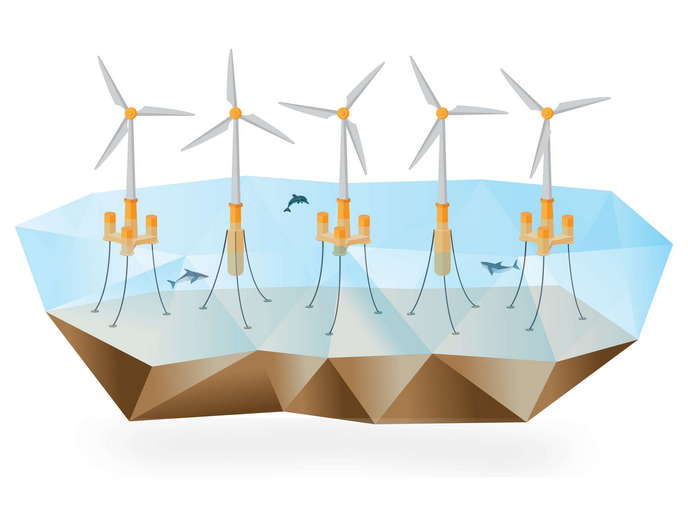

Floating offshore wind energy – harnessing the forces of nature

The world’s first fixed offshore wind farm was commissioned in 1991. Less than four decades later, the world’s first floating wind farm was commissioned in 2017. Floating wind turbines are larger than fixed and onshore systems – some projections predict that by 2035, the height of a turbine’s blades at their rotation peak could rival that of the Eiffel Tower. The potential for power generation rivals the capacity of efficient gas-fired power plants and some coal-fired power plants. However, keeping these systems in place and functioning in strong winds, buffeted by waves and currents under the sea is no easy feat.

Optimising station-keeping components, construction, operation and maintenance

Floating wind energy systems are secured in place via mooring lines attached to anchors. These so-called station-keeping systems (which maintain the turbine’s position within a defined radius) also protect the dynamic cables that export the energy generated. According to Jose Luis Domínguez-García of project coordinating entity Catalonia Institute for Energy Research: “COREWIND developed novel concepts to reduce costs including shared anchor and mooring lines among multiple turbines. These can cut related costs in half in the best cases.” The team also optimised two floating substructures: a concrete spar (a single large-diameter vertical buoyant cylinder ballasted at the bottom end) and a semi-submersible (multiple smaller columns and pontoons). In addition, Domínguez-García adds, “advanced controllers for floating wind played a key role in reducing operational expenditures.” Optimised transport and installation strategies and operation and maintenance procedures supported further cost reductions.

Digital tools promote optimised life-cycle designs and cost reductions

Researchers developed novel digital tools for optimal design of both the station-keeping system and the dynamic cables, allowing reductions in costs arising largely due to oversizing. The tools include a digital twin and a building information model. Another tool enables users to optimise the location of multiple wind turbines in relation to their neighbours (micrositing), leading to cost savings of about 5 %. “COREWIND developed the FowApp to evaluate the LCOE and perform a life cycle assessment (LCA). The project achieved and demonstrated the potential of a reduction in cost of more than 15 %, corresponding to a levelised cost of electricity (LCOE) less than EURO 100/megawatt hour (MWh), through disruptive innovations in floating offshore wind. In some cases, COREWIND’s optimisations achieved a LCOE of EUR 70/MWh. LCA demonstrated a significant reduction in the environmental footprint,” adds Domínguez-García. It is estimated that offshore wind has the potential to generate more than 18 times today’s global electricity demand. COREWIND has developed tools and technologies to help stakeholders exploit this amazing potential and accelerate our green energy transition.

Keywords

COREWIND, offshore wind, turbine, floating offshore wind, wind energy, wind farm, anchor, dynamic cables, mooring, micrositing