First model to accurately predict thin film flow behaviour

Thin film flow refers to the behaviour of a thin layer of fluid that spreads, coats or flows over a solid surface. It is observed in a range of applications, from biomedical to automotive. Understanding how thin film flow develops experimentally is time-consuming and expensive, so computational modelling is used instead. However, the complexity of the flow’s interactions makes this challenging. “Firstly, it’s difficult to measure the effects of tension at the interface between the fluid and surfaces, and the fluid and air. Secondly, the difficulty in characterising thin films experimentally at small scales, makes it hard to validate any model,” explains Pratik Suchde, principal investigator of the Marie Skłodowska-Curie Actions funded SURFING project from the University of Luxembourg, the project host. Suchde has created a novel computational model specifically designed to simulate thin film flow, which was successfully demonstrated in automotive and food processing industrial scenarios.

Model development

After analysing key assumptions underlying existing thin film flow models, Suchde identified some which limited their applicability. A bespoke model was then developed which assumed a thin film of fluid composed of multiple fluid droplets which cluster together. The thickness of the thin film is then built up based on the distribution of droplets. By calculating the forces exerted on each droplet, the team arrived at an equation (similar to the Cauchy momentum equation) which could be used as the basis for calculating subsequent fluid flow behaviour. The model was divided into three parts, with each undergoing independent validation. The first was validated against experimental data, the second employed theoretical approximations, while the third part was validated against existing thin film models available in the literature. “Finally the whole model was validated against computationally intensive bulk fluid flow simulations, setting a benchmark not reliant on thin film approximations. This also gave us a comprehensive understanding of how the three validated parts of the model function together,” adds Suchde.

Proof-of-application simulations

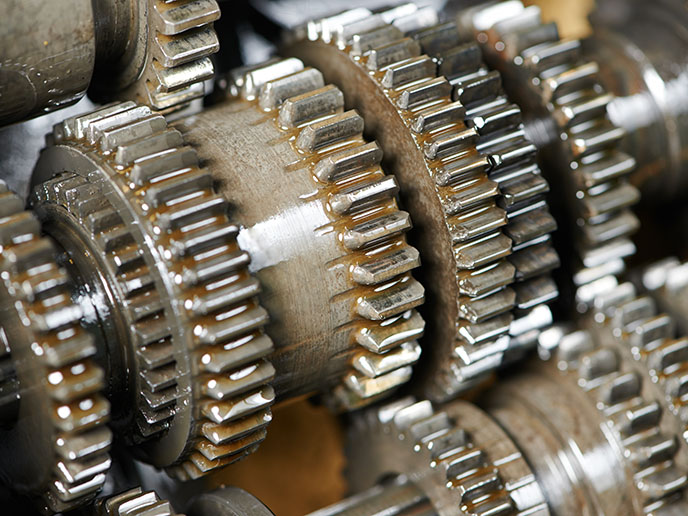

Looking to the automotive industry, SURFING was especially interested in gearbox lubrication, where typically an oil-based liquid is used to reduce the wear, friction and heat generated between gear wheels. Current thin film models typically assume a fully developed fluid film between the gear teeth, but in some situations (such as when lubricant is introduced after it has been fully depleted), it is crucial to model the formation of the thin fluid layer as well. Using data supplied by industrial partners, SURFING was able to accurately model this process. SURFING also considered the food processing industry – specifically the use of jet-propelled water-based cleaning fluids to remove food remnants from large trays. Again using data from an industrial partner, SURFING first used bulk fluid flow modelling to simulate the cleaning fluid jet. As the simulated jet hits the tray, the SURFING model’s algorithms automatically detected the formation of a thin film and switched from bulk flow to thin film modelling. “Our new model simulates such complex cases much faster than existing methods. It is the first time in fluid flow simulations that a model has demonstrated such dynamic adaptability,” says Suchde.

Optimising industrial processes

SURFING’s modelling could help shorten industrial development cycles, saving producers and ultimately consumers money. While improved designs could also help reduce maintenance costs. There will also likely be environmental benefits. For example, increased cleaning efficiency in the food processing sector could reduce energy consumption, while minimising waste. The team are currently improving the performance of their modelling, while continuing to explore the range of possible commercial applications.

Keywords

SURFING, fluid, flow, model, solid surface, simulations, automotive, food processing