Innovation in lithium battery design supports growth of electric vehicle industry

If the EU is to reach its goal of reducing 2021-level greenhouse gas emissions by 30 % in less than 10 years, there will need to be many more electric cars on the road very soon. Lithium-ion (Li-ion) batteries are at the heart of EV technology, for which Asian manufacturers currently dominate the market. The EU-funded SAFELiMOVE has developed a Li-ion battery that will improve the performance of EVs and open the door to increased European production of these batteries. According to project coordinator Maria Martínez: “SAFELiMOVE has delivered innovation in five main technology areas: development of nickel-rich layered oxide cathode materials; high specific capacity Li-metal anode materials; innovative hybrid ceramic-polymer electrolyte; deployment of optimisation techniques and study of different interfaces for effective Li transport; and know-how creation for the development of scale-up production of solid-state batteries.”

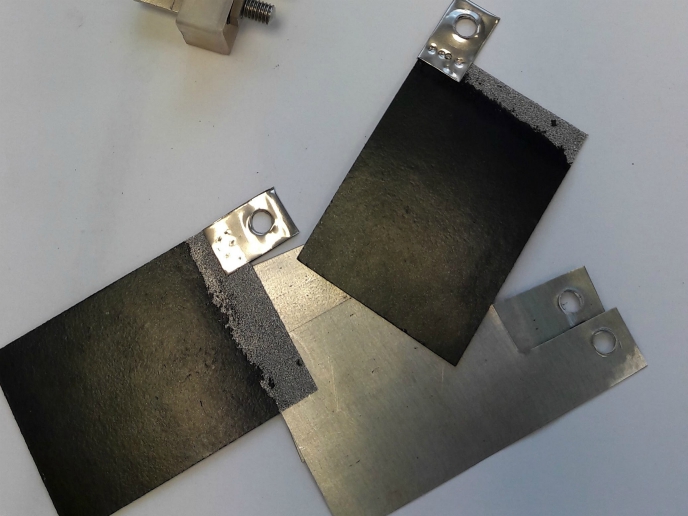

Batteries, before and after

Rechargeable Li-ion batteries dominate the market for EVs. These batteries are composed of a graphitised material for the anode, a lithium transition metal oxide for the cathode and a carbon-based liquid for the electrolyte. These batteries are energy-dense, but they present problems as well. For one thing, sourcing critical raw materials is bound to become increasingly difficult as the market for EVs grows. Also problematic are the deficiencies associated with the liquid electrolyte. The material is flammable, and exposure to too much heat is a hazard. The main objectives of SAFELiMOVE targeted the drawbacks of Li-ion batteries. The project team designed a battery that is free of graphite, uses a reduced amount of cobalt in the electrodes and has a solid-state hybrid ceramic-polymer electrolyte that may guarantee a safer operation of the battery compared to liquid organic electrolytes.

A wealth of improvements

The innovative battery design produced by the project has several positive outcomes. In addition to the increased safety inherent in using a solid-state electrolyte, the changes introduced by this high energy density lithium metal technology aims to increase the driving range of a vehicle by 300 km in a single charge. The future roadmap of SAFELiMOVE technology by 2030 envisions the decrease of the required time for the battery to recharge and the reduction of the overall cost of the battery. The team delivered many technological breakthroughs in battery design. According to Martínez: “these actions have reached the first generation of 1 Ah solid-state prototype with an average gravimetric and volumetric energy density of 250 Wh/kg and 500 Wh/L, respectively.” As future steps, before the end of the project, developers aim to manufacture a prototype with 10 Ah capacity and integrate it into a 24 volt battery module. In addition to providing improvements for EV owners in the form of better performance and safety, SAFELiMOVE provided the research and development around materials and battery design to push EU industries forward. The project consortium included researchers, materials producers, battery manufacturers, and automotive makers. High ambitions regarding sustainability goals have led to technological innovations across Europe. SAFELiMOVE is an excellent example of how such developments can simultaneously benefit the consumer, the manufacturer and the environment.

Keywords

SAFELiMOVE, solid-state lithium metal batteries, battery design, EVs, Li-ion batteries, electric vehicle, ceramic-polymer electrolyte