Smart materials for a smart society

Current technological applications require the development, processing and integration of smart materials with new functionalities, such as shape-morphing, self-sensing and self-healing. “The smart and sustainable society we are working to create needs intelligent components capable of being adopted in different applications,” says Costas Charitidis, professor of Nanotechnology and Nanomechanics at the School of Chemical Engineering, National Technical University of Athens. “Whether it be in the vehicle or home, new types of smart materials will be key to enabling many of the internet of things (IoT) devices that will drive society.” Helping us understand these new smart materials is the EU-funded SMARTFAN project. “We’re not talking about a new type of composite, we’re developing outside-the-box concepts for intelligent components and structures – functional materials capable of communicating, interacting and reacting with the environment,” adds Charitidis.

Starting really small

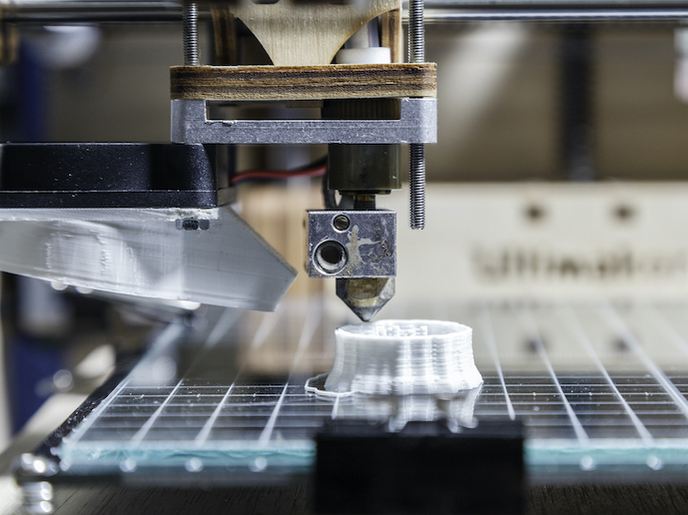

The project has set some challenging goals. These include creating materials that can alter their physical properties and shape, along with lightweight structures capable of providing real-time information on their in-service conditions. Material concepts based on bio-inspired solutions have also been considered. But achieving such big goals requires one to start small. For SMARTFAN researchers, that meant starting really small – like nano-small. “The first step was to develop nanomaterials with smart functionalities, which laid the foundation for creating nanocomposites,” explains Charitidis. “We also developed innovative surface treatments for carbon fibres that allowed the incorporation of carbon nanomaterials for functional sizing.” The project’s various partners also worked to exploit advanced composite manufacturing technologies, including continuous carbon fibre 3D printing, injection and compression moulding. All of these were fully optimised through modelling in atomistic, mesoscopic, macroscale and continuum models. “This work can serve as a blueprint for designing intelligent structures and integrating IoT solutions into smart architectures,” adds Charitidis.

The tip of the iceberg

Taking their work one step further, the project’s partners developed different use cases for the proposed smart materials. These include a lightweight, smart front wing for race cars, a self-sensing hood for kitchen ranges, an autonomous smart grabbing device for the space sector, and nano-carbon-based electronic structures for batteries and supercapacitors. “These concepts are just the tip of the iceberg in terms of what’s possible,” notes Charitidis. “They also serve as a springboard for developing new products with smart functionalities for the automotive and home appliance sectors.” The project has already inspired other EU-funded projects, such as Repair3D and EURECOMP, to develop smart recycling technologies. Carbo4Power, another EU-funded project, has exploited SMARTFAN’s technologies for offshore energy applications. “With 36 publications in peer-reviewed journals, along with a specialised training school and several workshops and conferences organised by the project, SMARTFAN’s impact will only continue to grow,” concludes Charitidis.

Keywords

SMARTFAN, smart materials, nanomaterials, internet of things, IoT, lightweight structures, nanocomposites, manufacturing, 3D printing