Improving the thermoelectric efficiency of nanostructured materials

Waste heat is produced all around us, wherever work is being performed: by the appliances running in our homes, by our cars, trains and buses, and by our factories and power stations. All this waste heat can be converted into useful electrical energy with the use of thermoelectric materials. Such materials should possess high electrical conductivity and low thermal conductivity. However, thermoelectric materials are typically inefficient. Since 2016, researchers supported by the EU-funded NANOthermMA project have been researching how to nanostructure materials to improve their thermoelectric efficiency. This efficiency is characterised by the figure of merit ZT. ZT is a function of thermal conductivity, electrical conductivity, absolute temperature and the Seebeck coefficient that measures the voltage induced in response to a temperature difference across a thermoelectric material. An efficient material with low thermal conductivity and high electrical conductivity would result in a high ZT value. Nanostructuring has already achieved significant reductions in thermal conductivity, so further improvements need to focus on increasing electrical conductivity and maintaining a high Seebeck coefficient. The problem with this is that these two quantities are inversely proportional to each other – any effort to increase one will reduce the other. Therefore, the NANOthermMA researchers have been investigating how to nanostructure materials that, as suitably described in an article posted on the ‘Open Access Government’ website, “relax the adverse interdependence” between electrical conductivity and the Seebeck coefficient. “Through a series of numerically intensive simulations using advanced software developed within the project, NANOthermMA has demonstrated theoretically how engineering at the nanoscale can break the adverse interdependence of these parameters and even achieve a 20-fold increase in the power factor – which is the product of the electrical conductivity and Seebeck coefficient squared, a quantity that directly affects the ZT,” writes Prof. Neophytos Neophytou of project coordinator University of Warwick in the article.

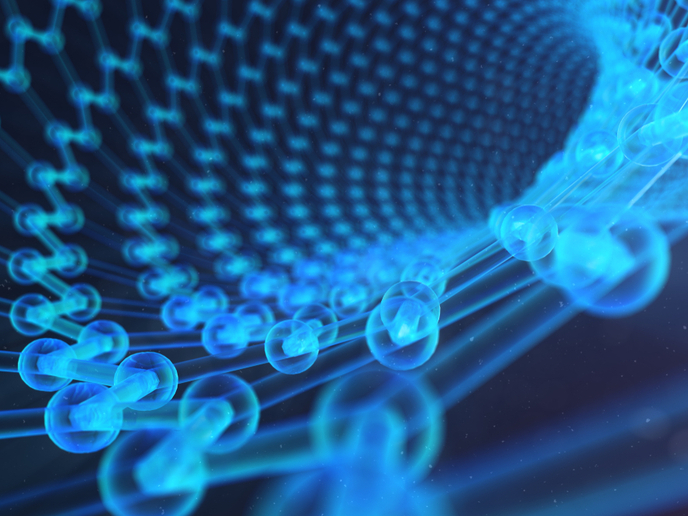

Nanostructured material geometry

The research team’s solution lies in nanostructured features such as nanograins and grain boundaries. “Within this geometry an additional species of dopant atoms is inserted at specified regions – dopant atoms are impurities which increase the electrical conductivity of the material. By carefully designing the sizes of the domains, the nature of the boundaries and the distribution of the dopants, what can be achieved is for the electrical conductivity to be primarily determined by the nanodomains whereas the Seebeck coefficient to be determined by the boundaries, and the two can be tuned independently,” explains Prof. Neophytou. The design of the nanostructured materials can be improved even more using hierarchical nanostructuring in which nanoinclusions are inserted inside the nanodomains. This helps to reduce thermal conductivity even more, and has the additional benefit of independently improving the Seebeck coefficient. The NANOthermMA (Advanced Simulation Design of Nanostructured Thermoelectric Materials with Enhanced Power Factors) team will investigate whether this theory can be put into practice. If successful, it could open the way to thermoelectric materials with high ZT values and ultimately greater efficiency. For more information, please see: NANOthermMA project web page

Keywords

NANOthermMA, electrical conductivity, thermal conductivity, Seebeck coefficient, thermoelectric, nanostructured