Deep-sea mining system for polymetallic nodules in the oceanic abyss

Polymetallic nodules found on the abyssal seabed of most ocean basins contain millions of tonnes of metals such as nickel, copper, cobalt and manganese as well as gallium and rare earth elements. Efficient deep-sea mining of these nodules requires a complete high-tech mining value chain but, to date, no integrated system of harvesting, vertical transport and surface processing has ever reached industrial viability. Simultaneously, it is vital to understand the biodiversity and the ecosystems of the deep-sea so that effective environmental impact assessment standards and regulation are put in place to respond adequately to future deep-sea mining and associated environmental challenges.

Seafloor to shore

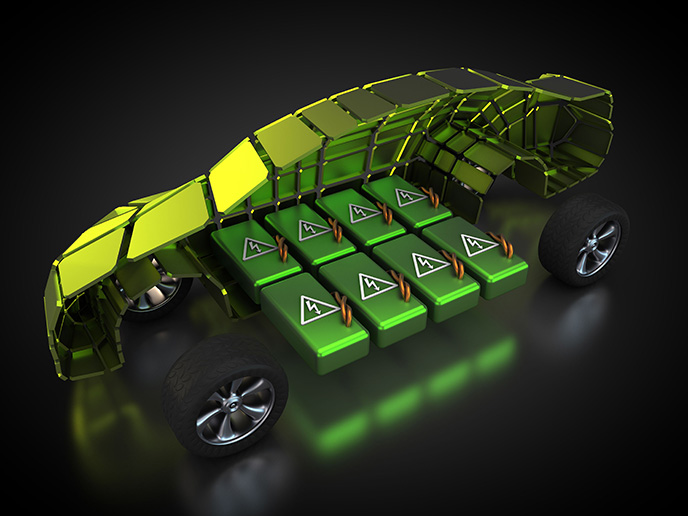

With EU funding, the Blue Nodules project has “designed the layout of the entire logistics chain while tackling the complex problem of environmental protection up to technology readiness level 6 (TRL 6),” outlines Laurens de Jonge, project coordinator. “This ambitious initiative is a major step in the development and testing of environmentally friendly seafloor harvesting and processing technologies for polymetallic nodules,” he says. At the centre of operations is the subsea harvesting vehicle Apollo II (pictured) used for collection of the nodules in water depths up to 6 km. The seabed crawler is connected to the offshore production vessel with a jumper hose to the vertical transport system and an umbilical cable, containing the data connections and electrical power supply. With in-situ processing at the seabed the nodules are separated from the sediments. On board the vessel, the nodules are dewatered and the deep sea water is returned to its origin. Another ship then takes the ore for processing on land, to extract the metals.

Minimal environmental impact

Using detailed computer simulations, the Blue Nodules team developed a nodule collection process in which disturbance of the seabed, which is essentially soft, sticky sediment, is reduced to a minimum. The model simulations for plume, noise and seafloor substrate alteration have been validated by lab experiments and field tests in 2018 and 2019. Priority was given to minimising the mobilisation of seabed sediment and the dispersion of suspended sediment in plumes, caused by the vehicle movement, nodule extraction and return water from the surface operations. For the future, the project researchers are working on reducing the kinetic energy of the plume released by the vehicle, which will in turn mean a smaller plume. They are also trying to remove hydraulic components to reduce the risk of contamination of the seafloor. “Environmental standards in legislation only make sense if they can be incorporated in the design process, in the operation and can be consistently monitored,” de Jonge emphasises. “By cooperation between science, industry and legislators during engineering and testing, Blue Nodules not only designed sustainable equipment but also developed a monitoring and sensor setup. This will measure, detect and objectively quantify the environmental impacts, like plume, noise and substrate alteration.”

Deep-sea mining to become a reality

The successor of Blue Nodules is the Blue Harvesting project. With many of the original partners, Blue Harvesting will focus on developing and improving the collector to reduce environmental impact while maintaining production rate and efficiency. Integrated field tests and pilot mining tests in a relevant offshore environment will attain TRL 7. Comprised of 167 Member States, and the European Union, the International Seabed Authority – ISA is mandated under the UN Convention on the Law of the Sea to organise, regulate and control all mineral-related activities in the international seabed area for the benefit of humankind as a whole. The ISA has issued regulations on exploration in international waters and is currently working on regulations for exploitation.

Keywords

Blue Nodules, mining, seafloor, deep-sea, environment, energy, polymetallic nodules, offshore processing, critical raw materials