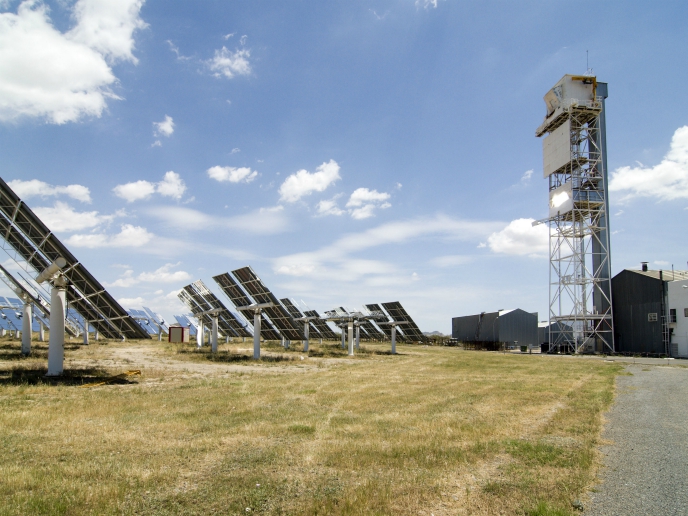

Water management tech for more financially and environmentally sustainable solar power plants

To function properly, steam-based power plants like CSP plants consume significant amounts of water. Such plants use up to 3 000 m3/GWh in areas where water is scarce. The majority of plants consume enough water to empty one Olympic-sized swimming pool per day. What’s more, sunny areas where CSP performs best are usually arid. Saving water is thus a key issue in ensuring CSP remains financially competitive and runs sustainably. To reduce water use in CSP plants, the EU-funded WASCOP project team developed a more flexible and adaptive integrated solution. Its toolbox is composed of different innovative technologies and optimised strategies that cool power blocks and clean solar field optical surfaces. “This holistic solution provides an effective combination of technologies adaptable to any solar field, power block cooling configuration and CSP plant location,” says Delphine Bourdon, project coordinator.“ The innovation supports a reduction in water consumption in the range of 70-90 % and a significant improvement in the water management of CSP plants.”

Optimising cooling and cleaning methods in CSP plant processes

Project partners modelled the toolbox components for cooling and cleaning operations. With respect to cooling, they studied technologies like delayed heat exhaust through different kinds of heat storage methods, a hybridised wet/dry cooler and an innovative versatile cooler. They designed and tested functional prototypes for each, and then fitted them with numerical models. This was done to predict the water and energy saved from each technology with the associated economic parameters for any kind of plant location and configuration. “The water traditionally consumed by power block cooling operations is cut by 90 %, and the performance of dry-cooled plants in high temperature operating conditions is increased,” explains Bourdon. For cleaning, different types of lab prototypes for soiling sensors show promising results by achieving correspondingly accurate soiling information levels. This data, together with the preparation of the developed soiling and dew model, will help plant owners to save water and schedule the cleaning cycle operations in a more convenient way. In addition, dust prevention technologies that comprise both dust barriers for the solar fields and anti-soiling coatings for absorber glasses and reflectors also show significant effects after being validated in outdoor operational conditions. “Water cleaning operations for CSP plants that integrate these technologies are expected to be half as frequent than without,” says Bourdon.

Huge water savings, better energy production

The WASCOP team successfully tested and validated the toolbox in real conditions at three testing sites in France, Spain and Morocco. Team members assessed the technical, economic and environmental impacts on CSP plants for all the developed technological solutions. Plant operators, plant owners and service providers have already shown interest in the technologies. “WASCOP has enabled end users to take a more global view of current water usage in CSP plants and the potential of CSP technologies and their applications,” concludes Bourdon. “It has identified different routes for overall improvement in terms of water consumption and commercial potential. Results will also support the development of renewable CSP energy in areas where competition for water access with local populations is becoming more notable.”

Keywords

WASCOP, water, CSP, CSP plant, energy, cooling, power block, solar field, solar power