Novel way to make graphene from renewable resources

Graphene has amazing properties – it is the strongest material in the world and can conduct heat and electricity better than anything else. Composed of a single layer of carbon atoms bonded together in a repeating pattern of hexagons, it is so thin it is considered to be two-dimensional. But more than a decade after scientists at the United Kingdom’s University of Manchester worked out how to isolate it, we are still not able to produce graphene cheaply and efficiently enough for widespread adoption. Spanish green tech company Biogenera Renovables has come up with a way of producing graphene from biogas produced by the treatment of waste from livestock and crops. EU funding for the project BIOGRAPHENE has allowed it to demonstrate and improve its prototype and to study the market for this new bioproduct. Researchers all over the world are proposing myriad ways of producing graphene. However, for Xavier Biela, CEO of Biogenera Renovables, producing the material sustainably is the priority. “Either we take action and look for technologies which don’t depend on oil or we continue with business as usual and wait for everything to fall apart,” he says.

Materials from manure

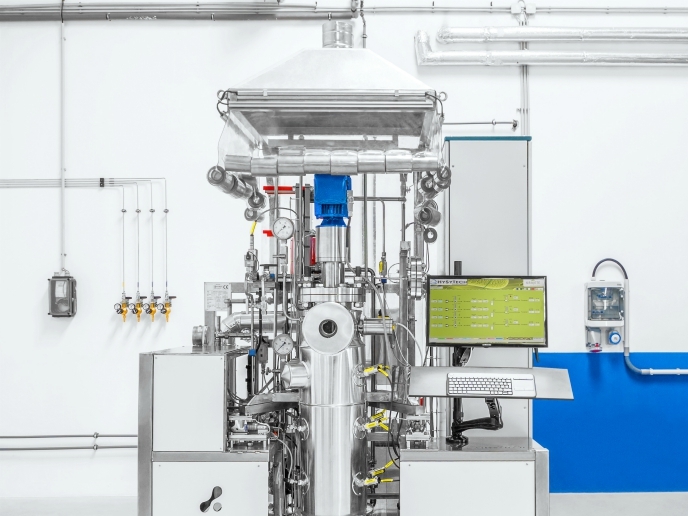

His team took biogas produced from pig slurry from a farm in Torregrossa, north-eastern Spain, and introduced this into a chemical vapour deposition (CVD) reactor adapted to handle methane, carbon dioxide or both at their laboratory in the city of Lleida. “The synthesis takes place, separating the carbon from the methane molecules and the carbon dioxide, and, as the carbon is heavier, it falls onto a catalytic plate. Then we use a roll-to-roll system to make biographene,” adds Biela. EU funds allowed the company to test the viability of their prototype by checking the processes for filtering and cleaning the biogas to produce the correct concentration of methane. They optimised the technical parameters for the CVD reactor and came up with a design for a biographene production unit. They also produced a cylinder of high-quality biographene 10 cm in diameter as a demonstration product. “This is feasible for any sector which does recycling and creates biogas. It is creating a new product from an existing process. It doesn’t interfere with the production process and you don’t need much biogas to make high-quality biographene,” explains Biela.

Orders instead of samples

When it comes to BIOGRAPHENE’s market research, the results are more mixed. Adding the material to existing products such as resin, concrete or asphalt could improve or even transform their qualities according to Biela. But it is hard to convince manufacturers to make big enough orders to justify ramping up production. “Everyone asks for samples. We have had plenty of conversations with manufacturers but in order to build an industrial-size reactor I need firm orders,” he says. Lack of clarity over what should be the selling price for graphene, in what is still an emerging market, adds to the uncertainty. Biogenera Renovables is now putting together a consortium with Italian engineering consultants Sustainable Technologies to apply for a second round of EU funding to take the project further.

Keywords

BIOGRAPHENE, green tech, graphene, biogas, recycling, methane, biographene production