‘Green’ hydrogen promises more renewable integration with more stable grids

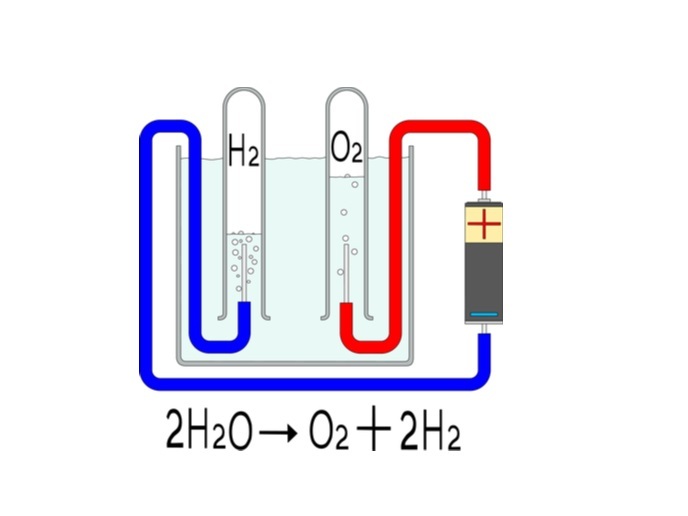

Normally, hydrogen is obtained from using a process called steam reforming. Although cost-effective, the process does not produce clean hydrogen as it uses natural gas and produces carbon dioxide and other contaminants. A non-polluting way of producing hydrogen is electrolysis which splits water into its main components – hydrogen and oxygen. The renewable fuel can serve as a potential storage medium for electric power that can either be used to fuel vehicles or converted back into electricity.

The challenge of handling solar and wind variations

While wind and solar have anchored their place as some of the most promising renewable energy technologies, the fact that they do not produce energy around the clock is certainly a major disadvantage. Using pure hydrogen gas as an intermediate medium is evolving as one of the most viable solutions that helps achieve the much needed constant power output required to maintain electricity grid balance. It can absorb excess green electricity though water electrolysis, store it for as long as it is needed and deliver it back to the network. By using water and green electricity generated by an array of solar panels or wind turbines, an alkaline electrolyser splits water molecules into its constituents, acting as a dynamic balance on the electricity grid able to increase or decrease its power consumption.

Efficient, cost-competitive alternative to low-carbon economy

The EU-funded ELYntegration project explored the technologies needed to overcome current limitations in the field of large power storage systems. Together, project partners from different countries across Europe successfully developed a robust, flexible mono-stack IHT alkaline electrolyser capable of producing 4.5 metric tonnes of hydrogen a day. This type of electrolyser is characterised by having two electrodes operating in a liquid alkaline electrolyte solution of potassium hydroxide or sodium hydroxide. “The newly developed robust, efficient and cost-competitive electrolyser creates the ability for the whole installation to deliver megawatt-scale electrical service to the network,” explains project coordinator Vanesa Gil. During the design stage, project partners considered many different aspects for successful technology implementation. These included assessment of the regulatory framework for electrolyser integration into the electricity grid, exploring current energy tariffs, and identifying new business models and use cases where electrolysers would benefit from very low electricity prices. “Another important consideration was the development and implementation of a control and communication system that interacts with the grid and renewable technologies so that it can balance supply and demand,” adds Gil. During the design of the megawatt system, project partners constructed models to simulate balance-of-plant performance under highly dynamic conditions and variable loads. They also developed new materials, electrodes and membranes, and improved assembly procedures. The membranes and electrodes were selected based on progressive testing on various scale levels. The focus was on decreasing gas-crossover at low current densities and over-potential at high current densities, respectively. Furthermore, new cell topologies were investigated to increase electrolysis efficiency. Technologies developed by the ELYntegration project could be scaled to meet market requirements. “The demonstrated improvements in the IHT alkaline electrolyser technology bring a flexibility that help retain the stability of electricity grids, thereby facilitating more use of renewable electricity,” concludes Gil.

Keywords

ELYntegration, hydrogen, electricity grid, alkaline electrolyser, electrode, stack