Screw anchors could enable floating deep-sea wind farms

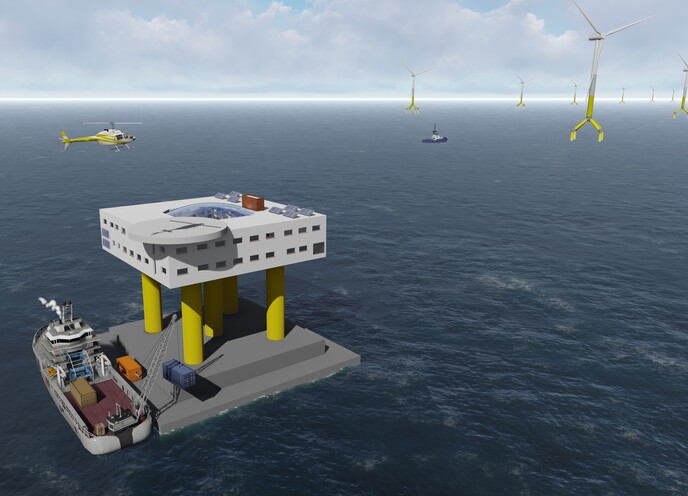

When civil engineers at the University of Dundee in Scotland began looking into whether offshore wind farms could share anchors, they expected to spend their time studying arrays of devices – how best to arrange nodding shoals of giant windmills out at sea. But as the SAFS project progressed, their research took a more back-to-basics approach by focusing on better ways of installing a screw anchor and predicting how it resists uplift. “The big question is to understand how screw anchors behave in sand,” says Jonathan Knappett, Professor of Civil Engineering at Dundee and SAFS coordinator. “If we are to meet ambitious targets on renewable energy, we need to move into much deeper water where existing foundation systems will not be cost-effective – we need a solution that floats.” As wind farms go deeper, the question of which physical foundations to use becomes more complicated and costly. The SAFS team believe that screw anchors – steel shafts with a helix at one end which could be used to anchor a floating wind turbine – are part of the solution. “One of the main advantages of these anchors is they can be installed with a very low level of noise and vibrations, unlike driven piles,” says SAFS main researcher Benjamin Cerfontaine, who undertook the research with the support of the Marie Skłodowska-Curie programme.

Whale-friendly installation

Not only are screw anchors better for marine animals, but the helix provides a strong tensile capacity or holding power, potentially reducing the anchor’s weight by 35-50 % compared to conventional piles. But there are no widely accepted design methods which can predict their behaviour during installation and over their lifetime. SAFS has produced a numerical procedure, validated against experimental tests, which allows you to calculate the load versus displacement relationship more accurately. “This allows us to assess the capacity, but also the stiffness, which is important for the dynamic performance of the floating turbine,” says Cerfontaine.

Working within constraints

The team further developed a simplified methodology for optimising the design of anchors within technical and structural constraints, such as an installation machine of limited size. “We can only do a limited number of experiments, but in the field engineers will have to design for a wide range of conditions,” says Knappett. “We are giving them a starting point – the size and shape of the anchor you should be putting in the ground – that can be further refined using the numerical procedure.” They installed small-scale screw anchor models in sand inside a geotechnical centrifuge to reproduce their behaviour at sea. This is helping to optimise the design but is also suggesting changes to improve the installation process. The technical requirements for installing large screw anchors offshore are currently beyond the capabilities of conventional equipment, so reducing these are key. Although SAFS has finished, the research team at Dundee has managed to attract follow-on industrial funding on the back of its results to carry on this line of research. “We are looking at changing the installation process to be able to install an anchor with less force,” says Knappett, who believes that modelling tools to predict this could ultimately prove to be one of the most innovative outcomes of SAFS.

Keywords

SAFS, screw anchors, design optimisation, offshore, wind farm, wind turbine, wave energy, renewable energy