Improved storage of excess electricity could make wind and solar energy more attractive

The EU is targeting a reduction in greenhouse gas (GHG) emissions by 80-95 % relative to 1990 levels by 2050. As a result, the contribution of renewable sources such as wind and solar to electricity production is growing among national electricity production systems. The fluctuating nature of these sources requires efficient technologies to store electricity in periods of excess production. The EU-funded ECo (Efficient Co-Electrolyser for Efficient Renewable Energy Storage) project set out to develop innovative technology based on solid oxide electrolysis (SOE) to convert electricity from wind and solar power into storable methane.

Converting electricity into storable molecules

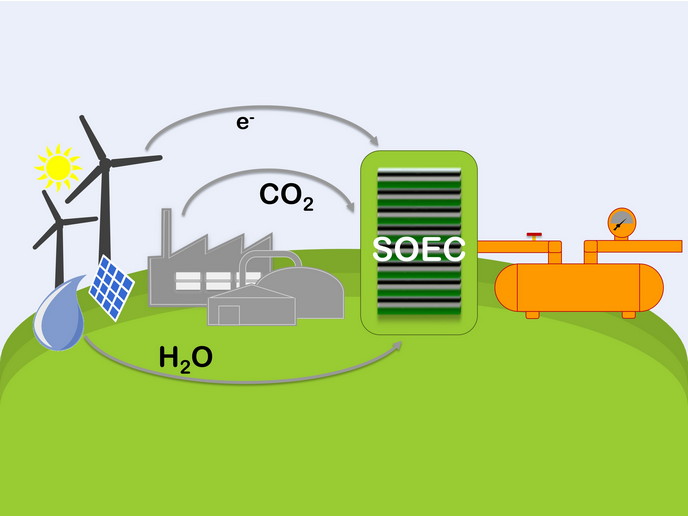

SOE cells (SOECs) produce H2 through electrolysis of H2O. Co-electrolysis of steam (H2O) and CO2 yields carbon monoxide and H2, a mixture known as syngas. This can be converted into various hydrocarbons such as e-gas (synthetic methane) through established catalytic processes. According to project coordinator Anke Hagen: “The overarching idea was to use electricity from renewable sources to produce synthetic natural gas, allowing for large-scale storage and distribution through the existing natural gas infrastructure in Europe, which currently can accommodate approximately 50 % of the electricity produced from renewable resources as methane.”

Teamwork ensures the achievements are more than the sum of the parts

Although the electrolysis process demonstrates conversion efficiencies close to 100 %, challenges remain regarding costs and lifetime. ECo successfully improved the performance and lifetime of SOECs and stacks, reducing investment and maintenance costs as well. As Hagen explains: “The SOEC is a composite of different layers, where materials’ compositions and structures determine performance and durability. The ECo project succeeded in delivering improved, truly cross-European cell versions through integration of components developed by different partners into a single cell. ECo demonstrated how SOECs cope with realistic conditions such as fluctuating electricity input without loss of lifetime, on both the cell and stack level yielding reduction of GHG emissions and efficiently converting ‘green’ electricity into storage media.”

Economic and environmental impact of integrating SOE technology into existing facilities

ECo designed an SOE plant and integrated it into three different existing CO2-emitting plants: a cement production plant, a biomass gasification plant, and a biogas production plant. Hagen elaborates: “Access to cheap and clean (CO2-lean) electricity is crucial for ECo’s economic viability. The share of renewables in the electricity input affects the environmental impact. All cases potentially benefit from an integration. Implementing the ECo concept into a cement plant provides the largest environmental benefits.” For the example of France with 23.6 % of the electricity provided by photovoltaics, savings of up to 239 000 tons of CO2 equivalent (in terms of global warming potential) were possible annually. As grid mixes in Europe become ‘cleaner’ in the future, the ECo solution will provide even greater benefits. ECo also established tools to assess the benefits for any specific local conditions. ECo’s improved SOEC technology could be instrumental in future renewable energy storage, helping the EU meet its goals for GHG emissions reductions while ensuring a stable and reliable supply of energy for its citizens.

Keywords

ECo, electricity, energy, renewable, carbon dioxide (CO2), solid oxide electrolysis cell (SOEC), SOE, greenhouse gas (GHG), methane, syngas, renewable energy, emissions, energy storage