Advanced electrochemical diagnostics promise to extend the healthy life of fuel cells

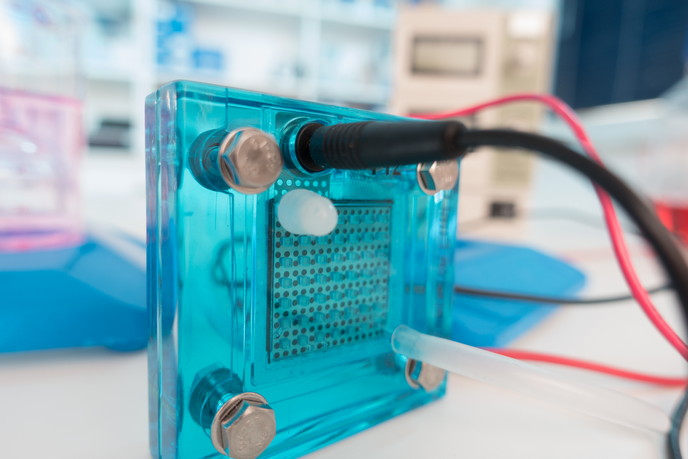

The Industrial Revolution was largely powered by steam engines and coal combustion. Today, steam turbine generators relying on combustion of fossil fuels produce over 65 % of the world’s electrical energy. Polymer electrolyte membrane fuel cells (PEMFCs) are among the top contenders for cleaner renewable energy. Applications include heat and electricity generation for homes or buildings (so-called micro-combined heat and power or µ-CHP) and for backup power. An advanced diagnostic and monitoring tool developed by the EU-funded project HEALTH-CODE promises to significantly enhance performance and decrease costs of PEMFCs in these and other applications. Simple reactions, complex diagnostics PEMFCs produce electricity directly from hydrogen and oxygen gases. Hydrogen gas at the anode is split into positive hydrogen ions (protons) and electrons. A catalyst-coated PEM separating the anode and cathode allows only the protons to diffuse. Electrons are forced through an external circuit to the cathode, generating electricity. At the cathode, the electrons and hydrogen ions combine with oxygen from the air, producing water that flows out of the cell. A number of things can affect both the functioning and lifetime of PEMFCs, including impurities in the hydrogen fuel source or inadequate supply of fuel or oxygen. The presence of sulfur-based compounds in PEMFCs, due to impurities in the gas stream after reforming for example, can poison the catalyst layer. Water balance is critical, as too much causes ‘flooding’ and too little can dry out the membrane. The HEALTH-CODE monitoring and diagnostic tool controls all these conditions and detects issues before they irreversibly affect the functioning and lifetime of PEMFCs. Advanced spectroscopy provides the solution According to project coordinator Prof. Cesare Pianese, “Previous monitoring approaches relied on numerous conventional sensors of temperature, pressure, mass flow rate and voltage among others. These require massive data analyses as well as modelling techniques to compensate for the lack of direct information on the electrochemical processes occurring inside the cells.” The HEALTH-CODE solution is a step-change for monitoring and diagnoses of PEMFC performance. The tool exploits electrochemical impedance spectroscopy (EIS), a well-known technique already used in numerous applications. Its wide utility rests in the plethora of information it delivers, covering electrode parameters and multiple electrochemical reactions that take place at different rates. Validation in a real operating environment confirmed the tool’s ability to detect a fault mode before irreversible damage occurs, more reliably than previous approaches, and with integration adding less than 3 % to production costs. The resulting reduced operating and maintenance costs will be a key incentive to uptake of PEMFCs. According to Pianese, “Exploitation will lead to improved maintenance, integration within new energy paradigms such as smart buildings/grid and enhanced implementation of virtual power plant management.” In addition, the technology could soon benefit applications beyond PEMFC-based µ-CHP and backup power. Among others, mobile systems (cars, buses, trains) could be the first fuel cell-based technologies to benefit from EIS-based monitoring and diagnosis. Innovation should continue well beyond project completion, thanks to two successful joint workshops generating heightened interest. Furthermore, there are plans for development of a ‘growth ecosystem’ nurturing cross-fertilisation among players at the regional, national and international level.

Keywords

HEALTH-CODE, polymer electrolyte membrane fuel cells (PEMFCs), monitoring, hydrogen, electrochemical impedance spectroscopy (EIS), electricity, fuel cell, micro-combined heat and power (µ-CHP)