Infrared thermography finds niche in plastics

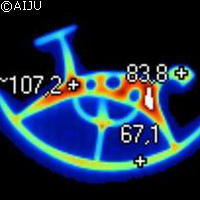

Researchers at the Spanish Toy Technological Institute (AIJU) have found that infrared thermography is a technique that can be used in the plastics industry, specifically for process optimisation and quality improvement. The research is part of the EU-funded CUSTOM-FIT ('A knowledge-based manufacturing system, established by integrating rapid manufacturing, IST (information society technologies) and material science to improve the quality of life of European citizens through custom fit products') project. Supported under the Sixth Framework Programme (FP6), financing for CUSTOM-FIT stands at EUR 9.25 million. Concerning the thermoplastic injection process, the researchers said extensive information about the transformation process can be gathered when thermographic images are taken of injected pieces that are either in the mould or have been extracted, or even in the mould surface itself. The AIJU team assessed the injection process on a toy hobby-horse mould in their study. The German-born British astronomer, Sir Frederick William Herschel, discovered infrared radiation in 1800. He observed that the heat going through coloured filters he used to look at the sun was dependant on the colour of the filter. Herschel shone the light through a crystal prism to produce a spectrum (the rainbow) and then measured the colours' temperature. Based on his observations, the temperature was higher on the red side. This side's light was invisible to the human eye. 'Caloric rays' was the term given to this radiation, and was later coined 'infrared radiation'. Around 80 years later, American scientist Samuel Pierpont Langley invented the world's first ever bolometer (infrared radiation detector). This detector could detect radiation by the rise in temperature generated by a heat-absorbing body. During the 1980s, researchers developed micro-bolometers, which are now being used in thermographic cameras. According to the AIJU researchers, all objects that have a temperature higher than 'absolute zero' (-273.15°C) produce waves in the infrared band. The higher an object's temperature, the more energy generated in a lower wavelength. They noted that infrared radiation, visible light and ultraviolet light are forms of energy found in the electromagnetic spectrum that vary in wavelength. The human eye can only see a limited range of wavelengths. However, thermographic cameras can detect infrared energy that is not visible to the human eye. These innovative cameras can register normal temperatures ranging from -20°C to 500°C, but they also can register from -40°C at the bottom end up to 2,000°C at the top end. According to the researchers, the thermographic cameras transform the infrared energy into an image with a colour map that indicates the temperature of the object at each point. The end result is a versatile camera equipped with an infinite range of applications in various sectors. The AIJU researchers are currently working with industry actors on various research and development (R&D) projects in the plastics sector.