New solution for open-air spent nuclear fuel dry storage

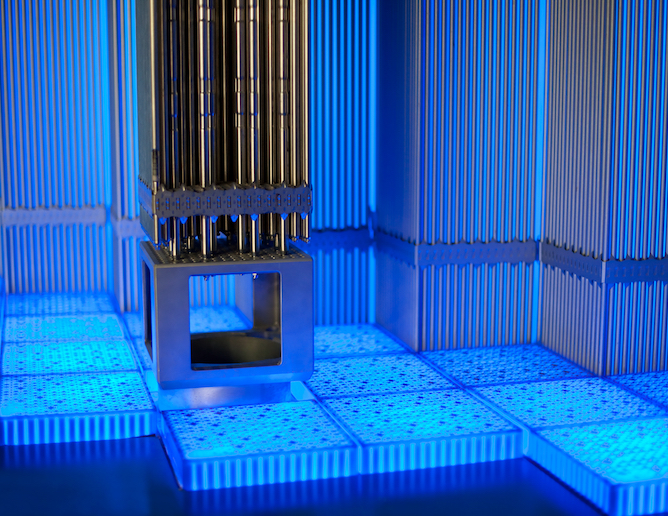

During the enriched Uranium depletion process, fission reactions produce a series of unstable radioactive isotopes. Trapped inside fuel rods, these turn the fuel assembly into a highly radioactive heat source. Once the rods’ fissile material is spent, they are removed from the reactor core and replaced. Nuclear power plants typically store SNF underwater in pools (wet storage) to cool them and protect against radiation leakage. Saturation of SNF pools has necessitated the use of dry storage, in which the rods are air-cooled and their storage casks used as protective shields. Nowadays, cask storage on an Independent Spent Fuel Storage Installation (ISFSI) is the preferred solution, pending permanent disposal. But these ISFSIs must comply with regulated dose limits, restricting the number of casks an ISFSI can store. The EU-funded ASM project came up with a cost-effective solution, known as the Auxiliary Shielding Module (ASM), for interim dry SNF storage that optimises quantity by using enhanced dual-purpose (storage and transportation) metallic casks. A new solution The ASM consists of several stainless steel rings with two flanges (inferior and superior) and two ferrules (internal and external) filled with concrete, which surround the metallic cask holding the SNF. After the preliminary design was completed, the solution underwent a verification process, including radiological, structural and thermal analysis, to enable design improvements. Radiological analysis optimised the shielding, including thickness and height, while taking into account ISFSI weight restrictions. Structural analysis assessed the likely influence of accidents based on known incidents and found that the ASM behaved successfully as an additional layer of protection against impacts, overturns or seism lifting. Thermal analysis checked the maximum safe temperatures, alongside the design of a ventilation system consisting of six intakes in the lowest ring, allowing air flux in the gap between the metallic cask and the ASM. “The ASM not only improves the metallic cask’s radiological behaviour but also provides superior thermal and structural performance, avoiding the long construction and permissions phases of alternatives such as covered ISFSI and at 32 % of the cost,” says project coordinator Mr Jokin Rico. Designed to be light, the ASM along with the metallic cask remains under 100 metric tons (MT), while reaching the dose reduction of concrete casks. Its thickness can be adapted according to dose requirements. It can also be installed using the same crane as for cask manipulation, making additional facilities unnecessary. A fast-growing problem Currently out of the 370 000 MT of SNF globally, two thirds (around 250 000 MT) remains in spent fuel pools. With SNF generation calculated to increase from 10 000 MT/year to 15 000, by 2030, space will have to be created by moving older SNF into dry storage, requiring over 25 000 casks, with an estimate that 70 % of this projected 560 000 MTs of spent fuel, will require dry storage by 2030. “ASM addresses the concerns of SNF stakeholders about the lack of a cost-effective way to store waste fuel that meets compulsory dose levels, while enabling a large number of containers in pre-existing ISFSIs,” says Mr Rico. The next phase will see the construction of an ASM prototype that demonstrates the manufacturing and installation process, as well as the assembly’s performance. Additionally, work is ongoing to achieve certification for the solution, now benefiting from ASM’s most recent fuel and cask data.

Keywords

ASM, spent nuclear fuel, fuel rods, casks, storage, power plants, reactor, uranium, radioactive, fissile