Low-cost miniaturised sensors ‘see’ trace gases

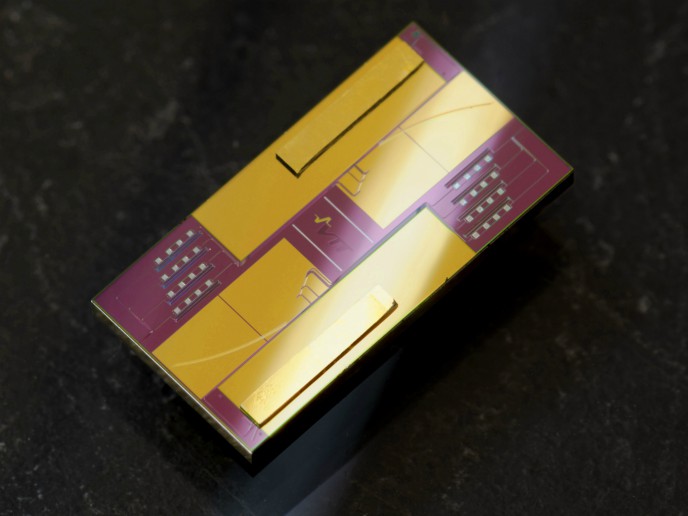

Infrared gas sensors are the cutting-edge technology for detecting harmful or explosive gases. However, currently available devices are either complicated, expensive or heavy. Furthermore, they are limited by low sensitivities and require large gas sample amounts. Led by a consortium of European research centres and industrial partners, the EU-funded project MIREGAS introduced breakthrough components that can be integrated for multi-gas analysis. Compared to conventional infrared gas sensor technologies, the new components provide better accuracy at a lower price – the wavelengths of light can be filtered more precisely and interfering gas components can be excluded. The infrared wavelength range helps detect the 'molecular fingerprints' of many trace gases. Fast and affordable multi-sensing The project consortium created a device that uses only one light source for multi-gas analysis, as opposed to several lasers. The light source utilises technology that was originally developed for optical communications applications – this minimises measuring costs compared to traditional spectroscopy measurement. The MIREGAS device can make multiple measurements with one tuneable and switchable multichannel optical filter and pick out individual gases from a mixture of emissions. These include methane, ethane, butane, propane, carbon dioxide and water. It has the potential to detect numerous gases simultaneously, which is useful in industrial processes and environmental monitoring applications. Project achievements MIREGAS is filling a gap in the market, as affordable high-performing infrared sources are not available. MIREGAS's tiny and low-cost gas sensor uses several breakthrough components that entail important benefits in terms of cost, volume production and reliability. These include a novel superluminescent light-emitting diode (SLED), a silicon photonic integrated circuit (PIC) spectral filter, moulded infrared optics, and high-volume assembly and packaging technologies. Project members demonstrated a wideband single-mode SLED emitting at 2.65 μm that reached an output power of nearly 0.5 mW with a 300 nm wide spectrum. To form a collimated beam from the SLED, they developed a new type of low-oxygen, heavy-metal-oxide glass that transmits mid-infrared radiation and is formed in a moulded-glass process called hot embossing. Moulded glass lenses that fit into a TO-can architecture were experimentally produced. The newly developed low-loss PIC owns two unique features: in addition to the conventional optical communications wavelengths at 1 550 nm, it is applicable for mid-infrared wavelengths; it also allows for integrating active devices such as laser diodes or photodetectors directly on the PIC chip. Packaging and assembly of the tiny sensor involved submicron alignment of the SLED that is flip-chip bonded to the silicon PIC. Sensing a bright future MIREGAS breakthrough technologies will enable project partners to reach a new level of selectivity and accuracy in multi-gas measurements at competitive price levels. “The possibility of tailoring the spectral output to match any wanted set of absorption lines with any desired bandwidth below 3 500 nm is the major advantage of our light source when compared to the single narrow line of a tuneable laser. Cost-effective multi-wavelength light sources are instrumental for the wide penetration of infrared gas sensors,” project coordinator Dr Pentti Karioja explains. “Our novel light source combining silicon photonics and infrared gas sensing will be advantageous not only for gas sensing but also for all kinds of mid-infrared sensors, process analysis technology, environmental and food safety, and security applications,” notes Pentti. This should open new business opportunities and strengthen their technological position in providing gas measurements for demanding applications.

Keywords

MIREGAS, infrared gas sensor, superluminescent light-emitting diode (SLED), photonic integrated circuit (PIC), mid-infrared, multi-gas, silicon photonics, moulded glass