The future of solar power with efficient and safe perovskite solar cells

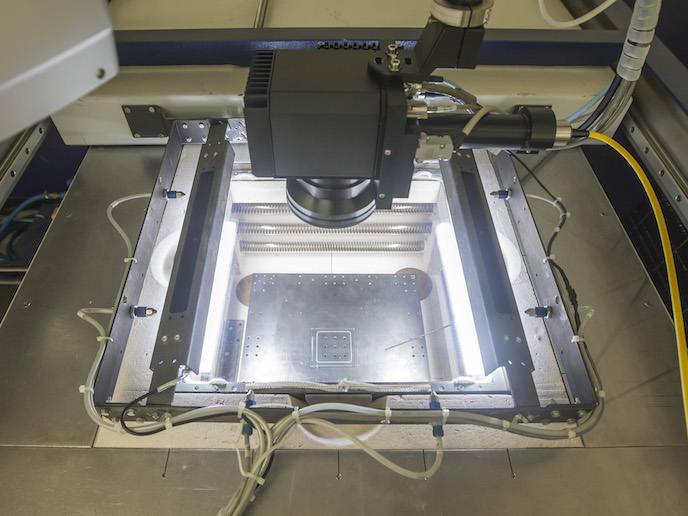

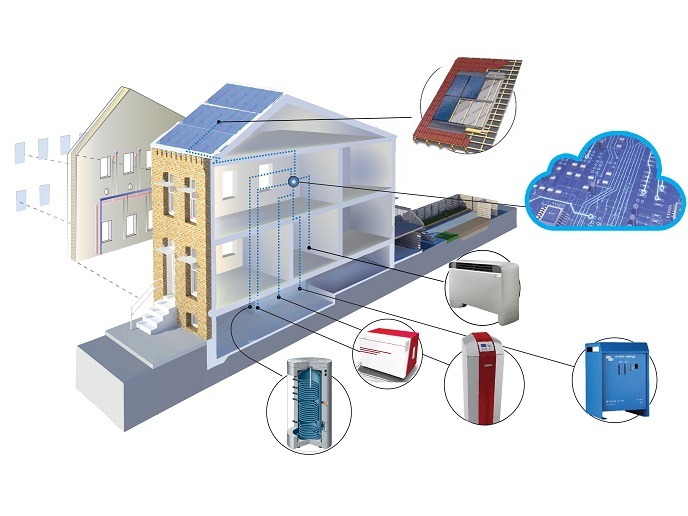

Perovskite (a crystal made of three components) solar cells could give the photovoltaics energy sector the boost it needs. The benefit of solar cells is that they can be made semi-transparent, while displaying a much higher kWh/nominal power ratio when compared to traditional silicon solar cells. The EU-supported GOTSolar project developed new perovskite formulations which were stable and easy to prepare, while displaying very high photovoltaic efficiencies; a so-called ‘triple cation’ formulation, now standard in the field. The project also created a laser-assisted glass sealing encapsulation process, at a temperature of around 85 °C, also a landmark. This invention allows encapsulation of very efficient perovskite solar cells without leaking lead, making it more stable and safer than alternatives. New materials and processes GOTSolar used a metal oxide scaffold to hold the perovskite, with the mesostructure assisting in the crystallisation of the perovskite, to form a highly efficient light harvester system. The assemblage was completed with solid-state Hole Transport Materials (HTMs) and a counter-electrode. “When you have a semiconductor that absorbs light, one electron of low energy is promoted to a higher energy level, leaving a ‘hole’ in the low energy level,” explains project coordinator Prof. Adelio Mendes. “The excited electron can flow to either surface of the semiconductor but it can only cross the interface when there is an Electron Extraction Layer on the other side, in this case titanium dioxide. The ‘hole’ can flow to either surface but can only cross the interface with an HTM.” The interactions of the electron extraction layer, the metal oxide scaffold, the perovskite absorber and the HTM layer were examined and measured to identify the circumstances in which electrons and the hole collection favourably optimise the whole device. This work enabled the team to push the PV power conversion performance up to 23.25 % efficiency for the lab-size instrument and to produce devices stable for 500 hours under 85 °C. Lead-less light absorbers were also developed in lab-size cells, which achieved a power conversion efficiency of 14 %. A 16 cm2 glass encapsulated prototype was built to demonstrate the scalability of production for the first perovskite solar modules with an energy efficiency of 12.5 % and a potential lifetime of 20 years. GOTSolar expects the first PSC panels to become commercially available by 2020. Doing more with less One key application of the technology will be for off-grid buildings. But for this to become viable, the cost of ownership will have to be lower than for traditional houses. This is obviously easier to accomplish in southern, sunnier countries. “For northern and central European countries, new silicon-PSC tandem cells will be critical as they are expected to display around 30 % power conversion efficiency, producing more power from a smaller photovoltaic area,” says Prof. Mendes. It is through GOTSolar’s contribution towards making these PV cells far cheaper via local production, that the project has made its greatest contribution. The team continues to explore the fundamental properties of PSC, to develop new formulations and architectures, as well as new HTM materials and more electrically conductive and transparent glass substrates. It is also pursuing new manufacturing strategies while improving the glass sealing encapsulation process, towards more efficient, cheaper, robust and aesthetic devices.

Keywords

GOTSolar, solar power, perovskite, photovoltaic, encapsulation, metal oxide, electron, sun