Exercising citizen power for a low carbon economy: a global first to make home fuel from atmospheric CO2

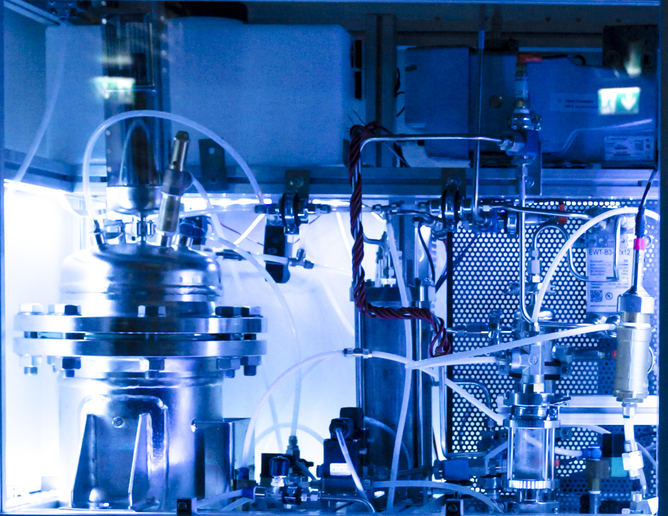

One area ripe for consumer engagement towards a low carbon economy is the heating sector, which was responsible for around 54 % of all EU CO2 emissions in 2016, according to Eurostat. To help reduce this, Gensoric (willpower – make your own fuel from CO2) received EU support to develop their willpower system - the first worldwide to tap CO2 to generate fuel for heating and other applications. The core technology is a patent protected, widely validated electro-biocatalytical technology that runs under ambient conditions. willpower produces methanol from air (atmospheric CO2) and water. As the chemical reactions occur under very mild conditions using standard enzymes, without hazardous materials or high-pressure tanks, it is deployable without specialist safety requirements. This opens up an enormous potential market. Intelligent electrodes The ‘willpower’ project designed electrodes which actually create the right setting for the desired chemical reaction. As project coordinator Mr Antonio Martinez explains, “It all started with the crazy idea of making intelligent electrodes. Electrodes traditionally provide voltage and deliver electrons, but ours also ‘feel’ the working temperature, expanding the scope of what they can do.” Here this means ensuring chemical reactions to deliver big end-product yields. Explaining the electro-biocatalytical process, Mr Martinez compares it to a reversal of what our livers do when processing alcohol, as it uses enzymes to cascade three chemical reactions to transform the alcohol into water, CO2 (that we expel) and heat. The team built a reactor chamber with their custom electrodes and enzymes, which once atmospheric CO2 is captured in water, facilitates the right sequence of chemical reactions to produce energy, stored as methanol. As methanol is extremely safe and easily transportable, it can be used on demand. Mr Martinez summarises, “When you realise that it would typically take 625 kg of lithium-ion-batteries to store as much energy as 10 kg methanol contains, it offers a very smart and efficient alternative.” Project expediency necessitated the use of commercially available, non-specific enzymes in the reactor chamber – achieving around 20 % efficiency. However, they are confident that customised enzymes can double that, and with additional measures (currently underway), efficiency could reach around 80 %. The system (reactors and CO2 capture units, based on space technology) was designed to be modular, meaning that it could be scaled according to need, making it flexible enough to use CO2 from other sources, such as exhaust systems. Revolutionary potential The technology could be a real game-changer. As Mr Martinez says, “Firstly, the idea that combustion always pollutes the environment is now proved false. Not only is our system clean and CO2 neutral, but CO2 is actually a useful ingredient. Also, for the first time, citizens will have direct access to decentralised energy production.” Aside from emissions reductions, willpowe’ aligns with other EU strategies. For example, by offering alternatives to oil and gas imports from unstable regions. Also, primarily using energy from renewables means it can store that energy at a greater capacity than power packs and batteries. To get to market, the team is optimising efficiency and costs, by testing new materials for electrodes and customising the catalytic enzymes to boost methanol output. Additionally, as methanol burns for heating it releases water and CO2, and the team wants to reuse these as inputs for yet more methanol.

Keywords

willpower, CO2, energy, methanol, battery, carbon neutral, electro-biocatalytical, heating, fuel, catalytic enzymes, reactor