The super-insulation technology for buildings & construction comes of age

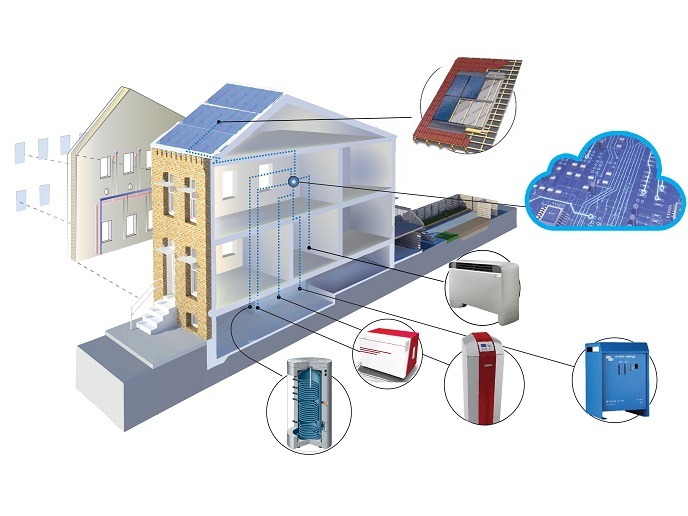

Energy efficiency has become a leading consideration in the construction industry. Innovations such as advanced aerogel-based composite (AABC) materials or also called super-insulation panels are being used in ingenious ways to address the energy efficiency challenge. Against this backdrop, the EU-funded the HOMESKIN project has developed the AABCs that show the lowest thermal conductivity of all insultation materials on the market. “We created new insulation that’s not only thermally superior but also much thinner, lighter, safer and better in terms of reducing emissions from buildings,” says Dr Brice Fiorentino, Innovation Project Manager at Enersens France and project coordinator of HOMESKIN. This is especially significant since buildings are currently responsible for 40 % of the global energy consumption and 36 % of CO2 emissions in the EU. “By improving buildings’ energy efficiency, we can reduce the total EU energy consumption by 5-6 % thank to performant insulation and lower CO2 emissions by about 5 %,” reveals Dr Fiorentino. Superior insulation in every respect Importantly, the new technology can be applied both to new buildings and existing older buildings, be it indoors, outdoors or on rooftops. The technology was developed by 10 partners from 5 European countries, bringing together key construction stakeholders in academia and industry. “After intensive testing, we succeeded in identifying the best material for producing cost-effective, non-flammable and eco-friendly super-insulation panels,” highlights Dr Fiorentino. “The silica-based material offers insulation that’s three times more effective than any standard insulation material, in addition to boasting good acoustic performance and excellent mechanical properties,” he adds. Another major advantage is that the insulation takes up less space than current market alternatives. “This means that the walls of any house or building can be thinner, saving valuable indoor space,” explains Dr Fiorentino. In more ways than one, HOMESKIN has surpassed the state of the art. It achieved superior thermal conductivity, improving insultation by at least 30 % and creating one of the best performing insulation solutions on the market, in line with all European requirements. Promising market prospects Currently, the project consortium is seeking CE certification to facilitate commercialisation as it expects large-scale adoption of its new product. “If HOMESKIN solutions are adopted massively, the technology could reduce the energy consumption of buildings by 30 to 60 %, depending on building’s age and climatic area,” illustrates Dr Fiorentino. Commercially, this has huge implications: if only 1 % of the existing European building stock – which totals 160 million buildings – is renovated each year, this will lead to 20 million m2 of new insulation per year. From an environmental point of view, considering that we will begin by the renovation of the oldest buildings which represent 35 % of the buildings stocks and 57% of the average energy consumption per annum, “we have estimated a reduction of 2.5 % in global energy use after 10 years and more than 5 % after 20 years, as well as a reduction of 30 % in CO2 emissions from buildings,” concludes Dr Fiorentino. If these figures are anything to go by, AABCs are no doubt set to revolutionise insulation in the sector. Economically, the HOMESKIN project has prepared the industrial roll-out of a leading key enabling technology for Europe. According to the latest estimates, manufacturing of the AABC materials is expected to generate about EUR 73 million per year in turnover in 2027 and a Compound Annual Growth Rate of 40 % (2017 to 2027) with the potential creation of 300 jobs across the value chain.

Keywords

HOMESKIN, building, insulation, aerogel-based composite, construction, energy efficiency, energy consumption