LbL technology applied to graphene oxide

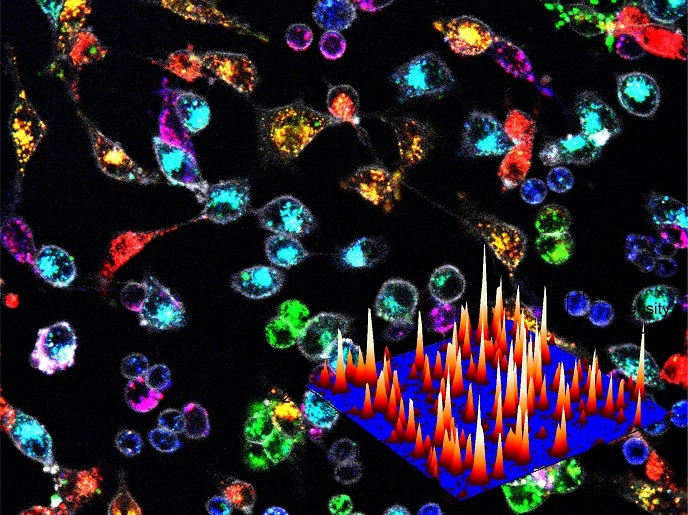

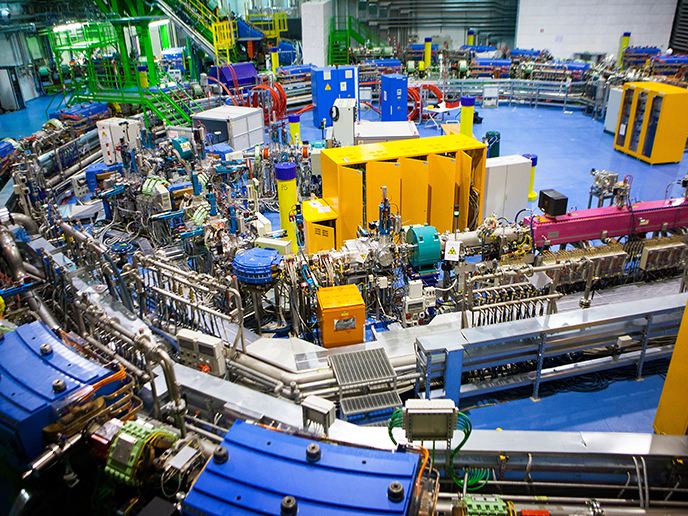

Graphene is often presented as a supermaterial for its out-of-the-ordinary strength, thinness, conductivity and optical properties. But its potential reaches a whole other level when combined with other materials of different natures. By creating these hybrid materials, graphene properties can be tweaked. This provides researchers with new and exciting prospects for applications, and it can also guarantee better integration of graphene in devices. With this in mind, Dr Sergio Moya from the Centre for Cooperative Research in Biomaterials (CIC biomaGUNE) kick-started the HIGRAPHEN (Hierarchical Functionalization of Graphene for Multiple device fabrication) project in March 2014. Using layer-by-layer technology – a simple procedure for the functionalisation of surfaces based on the stepwise deposition of oppositely-charged molecules or materials – he aimed to develop a versatile, generic procedure for the fabrication of hybrid devices coupling graphene with polymeric, organic and inorganic materials. “The driving force behind layer-by-layer (LbL) assembly is the electrostatic interaction between the assembled components,” Dr Moya explains. “Initially, this technique has been developed for the assembly of polyelectrolytes, that is, polymers with multiple charged monomers. But it has since been extended to multiple components: LbL film polyelectrolytes can be combined with nanoparticles, with lipids, cells, graphene oxide, etc. It offers a simple and powerful way to engineer interfaces while avoiding covalent chemistry, and it has potential in many applications – from nanofiltration membranes to optoelectronic devices, smart coatings, and drug delivery.” The project went a step further by specifically focusing on the combination of graphene oxide with metal and metal oxide nanoparticles, as well as polyelectrolytes, whilst contemplating potential applications in energy storage and catalysis. Although the LbL technique is widely used in surface engineering and thin film fabrication, HIGRAPHEN’s use of LbL to assemble heterogeneous components with graphene oxide is particularly innovative. Dr Moya and his team first proceeded by synthetising different nanomaterials such as zinc selenide (ZnSe) quantum dots, magnetic nanoparticle, and electroactive polymers like polyaminobenzylamine (PABA), before integrating them into LbL films with multiple components including graphene oxide. The HIGRAPHEN team then integrated the assemblies into macroscopic anticorrosive coatings and devices for optoelectronic applications and energy conversion. “One of the main challenges we faced was to obtain a dense arrangement of graphene oxide in combination with polymers. This led to the development of different approaches to coat the graphene oxide and combine it with nanoparticles,” says Dr Moya. Overall, the project’s most important outcome is the demonstration that graphene oxide can be assembled to produce dense polymer composite, and that it can be easily integrated with metal nanoparticles for catalysis. Whilst HIGRAPHEN will only draw to a close in March 2018, Dr Moya says that project partners are already pursuing interesting new research directions based on project outcomes for device fabrication and catalytic applications.

Keywords

HIGRAPHEN, Layer-by-layer, graphene, composites, optoelectronics, energy conversion, nanomaterials