Are microalgae the feedstock of the future?

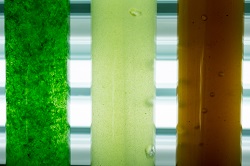

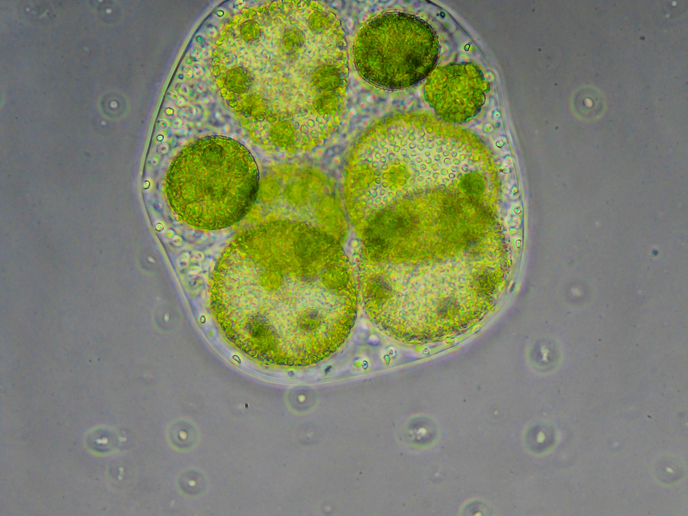

Europe is transitioning from a wasteful fossil-fuel based economy towards a more sustainable, circular economy. In order to complete this transition, viable cost-effective replacements to fossil-based products must be found. One possible avenue of opportunity is microalgae, which are being investigated as a promising new renewable feedstock for chemicals and plastics. ‘A key advantage of microalgae is that they can be cultivated on non-arable land and yield valuable compounds for chemical industries,’ explains SPLASH project coordinator Dr. Lolke Sijtsma from Wageningen Food & Biobased Research in the Netherlands. ‘If microalgae could be sustainably cultivated at an industrial scale, then this would help us to decrease our dependency on fossil feedstocks, and potentially contribute towards climate mitigation and reduced pressure on land resources.’ Understanding algae The EU-funded SPLASH project has taken a significant step forward in this quest by demonstrating that hydrocarbons and polysaccharides can be extracted from the microalgae species Botryococcus braunii and converted into renewable polymers. By focusing on producing high value molecules, the project represents an important step forward in kick-starting an economically and environmentally sustainable market for microalgae-based products. ‘We wanted to first understand at a fundamental level how these algae produce hydrocarbons and sugars,’ explains Sijtsma. ‘From this, we were able to make a kind of metabolic map. If you go to a big city like Amsterdam and want to get from A to B, then there are a number of possibilities open to you. In the same way, we developed a map that shows scientists how they might go about developing molecules by mapping the various genetic pathways.’ Algal cultivation and product formation was optimised at small scale and this process was then demonstrated at pilot scale. Hydrocarbons and carbohydrates were successfully extracted from selected strains and converted into viable products. Sustainability assessments and market analyses were also carried out in order to identify a path towards eventual commercialisation. Benefits along the supply chain The entire supply chain – from cultivators through to industrial manufacturers and end users – was involved in this project, and all ultimately stand to benefit. ‘Our findings provide industrial partners with an excellent opportunity to conduct further pilot tests of their technologies in order to achieve more reliable industrial solutions and to scale up production,’ says Sijtsma. ‘At the same time, end users like chemical companies now have a better understanding of how they can use biological raw materials in products, and also a clearer picture of the challenges ahead. Existing chemicals are relatively cheap, so the production and cultivation of microalgae-based products must become more price-competitive.’ Sijtsma notes that there might be better opportunities in the specialised products sector in the short term, since these have higher development value and require smaller amounts of raw material. ‘One interesting area of discovery was the extraction of lipid components, which could be used in cosmetics and other high value products. We are not in a position to say however that we’ll be ready for market in a year’s time with this; there is still a fair amount of research that must first be implemented.’ Nonetheless the SPLASH project is a step in the right direction and a necessary investment in Europe’s future circular economy. ‘Thanks to the work of this project, we now have a group of highly skilled professionals with expertise in microalgae cultivation, processing and chemical conversion systems coming through,’ notes Sijtsma. ‘This will help to ensure that bioplastics from microalgae can become a reality.’

Keywords

SPLASH, feedstock, microalgae, lipid, cosmetics, chemicals, hydrocarbons, chemicals, fossil fuels