Organic chemical production made greener

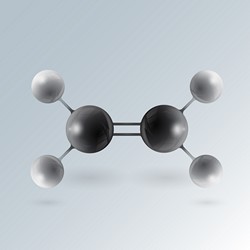

Chemical products are made when substances known as reactants are changed to other substances by breaking and forming chemical bonds. These bonds are created either when atoms within molecules share electrons or when atoms with opposite charges are attracted to each other. The process of chemically transforming reactants to products is often inefficient and generates a large amount of hazardous waste. The EU-funded HYPERCAT (Hypervalent chemistry and catalysis) initiative worked to develop more environmentally friendly ways to make organic chemical products – in particular, complex small molecules. One way to make reactions more efficient is to use a catalyst, which helps to break and form bonds by both receiving and donating electrons. To create carbon bonds in organic molecules, chemists often use expensive metals like palladium, nickel or platinum as organometallic catalysts. HYPERCAT looked at whether the non-toxic, naturally abundant elements boron and silicon could be used in place of traditional organometallic catalysts to make organic compounds. Under specific conditions, boron and silicon are useful electron carriers. To develop a bigger repertoire of non-toxic organometallic reagents for organic chemists to use, researchers sought to understand how they behave under these conditions. Team members then developed ways to make boron- and silicon-based reagents with specifically designed chemical structures. These reagents can be used to make complex molecules with structures that are difficult to create by other methods. The organic molecules that HYPERCAT created in this way, called alkenes, are among the most important and widely used industrial compounds globally. By providing inexpensive, environmentally friendly chemical pathways to produce these and other organic molecules, HYPERCAT has made an important contribution to green chemistry.

Keywords

Organic chemical production, chemistry, catalysts, HYPERCAT, organometallic, boron, silicon