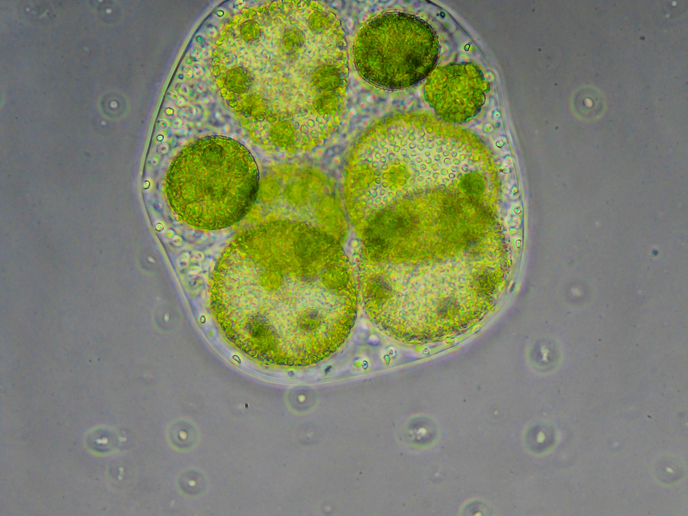

Sustainable chemicals from algae

Long known for their ability to produce a vast number of different bioactive compounds microalgae hold great promise for new products in the chemical and pharmaceutical industries, as well as the food sector and energy sectors. What’s more, algae have rapid growth rates in CO2-rich environments. The EU-funded project BISIGODOS, which involves 15 other partners from all over Europe, was established to select and cultivate new varieties of microalgae to facilitate the optimisation of the extraction of products with high added value for industry. Consuming CO2 from industry emissions BISIGODOS is revolutionising how industrial carbon emissions are used. The project succeeded in feeding algae in photobioreactors with CO2 sourced directly from industrial emissions to ultimately obtain different substances for the production of adhesives, paints and inks. To this end, researchers improved algal strains, redesigned photobioreactors and developed ways to separate and purify algal components. In BISIGODOS' prototype, marine microalgae efficiently convert CO2 and sunlight into kilogrammes of biomass. Researchers then extract lipids from algal cells to be converted into fatty acids. These are used to produce bio-based adhesives and resins for flexible and sustainable packaging. The remaining fat-free algal cells are then used to produce amino acids for the food and cosmetics industries. Various algae-derived chemicals are also used for anti-corrosive paints, bio-based resins for inks and compounds for the hair care industry. Overcoming challenges One of the most critical issues facing the consortium was to separate algal components from the liquid phase. “The separation process depends on the component physical or chemical properties. Any change in properties such as biomass type, temperature, water content, or the catalyst used modifies the product composition and can lead to taking different separation steps,” points out project coordinator Ana Palanca. Another important aspect has been the high costs of the algae-based products compared to those depending on fossil feedstocks. “The significant cost of growing microalgae can stall further development or prove to be a barrier for commercial exploitation of this promising technology. The challenge of driving down product costs depends on making biomass and downstream processing more cost competitive in the future,” points out Palanca. Although there is a wealth of work still to be done to achieve further progress, algae-based products have revealed significant potential compared to their petrol-based counterparts. For example, algae can be used as an alternative protein source as in addition to the high protein content they are also rich in vitamins and minerals. Microalgae are also a source of naturally occurring surfactants that are both biodegradable and cheaper. The appeal of algae is its ability to contribute to greenhouse gas reduction while serving as a feedstock for production of valuable products. BISIGODOS’ advanced process effectively transforms microalgae into bio-based chemicals to maximise the value of bio-feedstock and reduce CO2 waste.

Keywords

BISIGODOS, microalgae, CO2, biomass, fatty acids