Heat pumps help reduce CO2 from cities

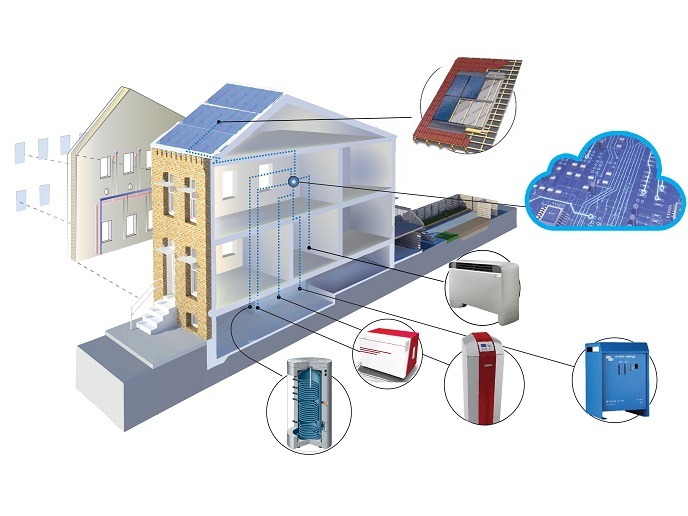

Due to limited space in cities, heat pumps have to be integrated into existing buildings and must be compatible with existing heating systems. In addition, installation and running costs must be sufficient to make the changeover to heat pumps economically viable. The GREENHP (Next generation heat pump for retrofitting buildings) project aims to meet these challenges by designing a next generation heat pump for retrofitting in buildings. The GREENHP system will be installed in apartment blocks or commercial buildings with a living area of around 600 metres squared. It is based on a variable capacity air/water heat pump and is capable of supplying up to 30 kW of heat for space heating and domestic hot water. The project team is also analysing how the new heat pump can dovetail with large energy systems like a smart grid environment. All the key hardware components have now more or less been finalised and tested, including the compressor, condenser, evaporator unit and fan. The compressor was developed by the project to cope with the heat pump’s special refrigeration cycle. By using EVI (Enhanced Vapour Injections) it is possible to cover the full operating range of an air/water heat pump. The compressor is also designed to handle both space heating and domestic hot water preparation processes as efficiently as possible. A key innovation has been to select propane R290 as the refrigerant for the heat pump. Using R290 together with MPE-tubes has allowed the research team to reduce significantly the overall amount of refrigerant required by the heat pump system. Propane’s high volumetric cooling capacity also makes it possible to use smaller components, which will reduce the size of the final system. However, the main reason propane has become the preferred option is that it has a very low global warming potential compared to synthetic alternatives – which is key to cutting direct emissions. A new fan has been designed for the evaporator unit after careful consideration of about 100 different blade geometries. The chosen concept has the blades swept slightly forward which allows for the most efficient energy consumption under expected operating conditions. The fan and evaporator have been through rigorous tests to assess their ability to deal with icing issues. In addition, a nozzle fitted behind the fan reduces noise emissions. A bionic distributor has also been built for the system to provide smooth, efficient distribution of the refrigerant. Meanwhile, work has moved ahead in the development of an energy management controller which can work with the heat pump. Testing of the controller is in its final stages and its hardware box has been built. Researchers have applied algorithms to make some initial assessments of how the controller will marry up with the heat pump. ‘The next stage is to bring all the hardware together to assemble the GREENHP prototype. Testing, which is scheduled to begin in early 2016, should take about two months to complete,’ said Project Coordinator, Andreas Zottl. ‘After that, there will be further tests which will see the heat pump linked with the newly developed control system. We need to assess how the controller works with the heat pump, but also how the entire unit interacts with smart grid operations.’

Keywords

Heating system, smart grid, heat pump, GREENHP, energy efficiency, retrofitting, buildings