Speeding-up the production of green plastic

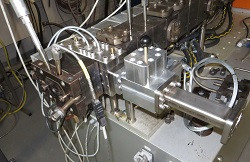

Demand for biobased polymers is growing fast, but current production technology uses catalysts containing metal which can be an environmental and health hazard. One EU-funded project is developing a new reactor to make the process metal-free. The INNOREX project is replacing metal-containing catalysts with organic catalysts. It has also developed an innovative reactor using alternative energies that allow for a continuous and precise metal-free polymerisation process. ‘Our project demonstrates methods that enhance the production of polymers allowing for a large scale production at a reasonable price,’ explains Björn Bergmann, INNOREX project coordinator. The particular polymer used by INNOREX is polylactic acid (PLA) which is mainly used in food packaging and single use cutlery, among other things. ‘PLA is a polymer built up from long chains of lactic acid molecules. The lactic acid itself is produced by bacteria which are fed by corn, for example, so the feedstock of the polymer is renewable,’ Bergmann says. ‘Another big advantage of PLA is not only that it is bio-based but that it is also biodegradable. This means that when it is disposed at industrial composting plants, the polymer is digested by bacteria ultimately resulting in water and CO2,’ he adds. INNOREX works by demonstrating ways to enhance reaction kinetics, speeding up the process of polymerisation using twin screw extruders. Currently twin screw extruders are not used for polymerisations on a large scale because they are not efficient and precise enough as well as not offering sufficient residence times. But INNOREX is working on overcoming this by using alternative energies - microwaves, ultrasound and laser light. These techniques can achieve an enhanced, controlled and efficient polymerisation of PLA in a twin screw extruder. ‘We managed to introduce microwaves and ultrasound into the extruder which provide additional highly targeted energy and enhance the reaction. We also adapted an online viscometer which can continuously analyse the material and tell us how complete the polymerisation process is. We then used a second type of extruder to purify the product, improving its quality,’ Bergmann explains. He continues: ‘We hope to see more processes switch to using twin screw extruders, leaving out solvents, to make the process more environmentally friendly. We also hope that our technology will help other processes that use the same intensified production processes to be brought onto the market. Producing PLA in twin screw extruders has been done before. But without intensification it has not been economically beneficial to do so – yet.’ The project is hoping to help the EU achieve its ambitious environmental goals. ‘The intensification process reduces the use of energy. Moreover, by removing the need for solvents, we have also demonstrated the potential to cut energy use and minimise our CO2 footprint,’ Bergmann explains. By using a biobased polymer, INNOREX is moving away from fossil fuel resources to renewable feedstocks. Finally, the project can help reduce the amount of waste in landfill sites since the polymer is biodegradable. INNOREX now hopes that its partners will now develop the technology further, leading to eventual full-scale commercialisation.

Keywords

INNOREX, biobased polymer, PLA, fossil fuels, alternative energy, renewable feedstock, energy efficiency