Disruptive innovation delivering industrial solutions that make a difference

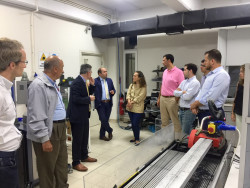

The CITyFiED project met at Istanbul Technical University, September 2017 and spent time visiting fellow consortium member Mir Unique Solutions and their in house centre of technology, called MITEC, Mir Innovation and Technology Centre. Mir have been at the heart of district heating solutions developed in Soma, Turkey and developed an approach to industrial innovation benefiting projects around the world. Although best known for their district heating pipe technologies, the CITyFiED site visit revealed a multi-disciplined staff spanning agriculture, composite materials, chemistry, mechanics, construction, electronics and software. Deputy General Manager, Dr Zafer Gemici explained to the group how Mir acts as an incubator for technology excellence – harnessing a continued dedication to applied research learning, strong collaboration with universities and a desire to see minimum scale prototypes all the way through to successful spin offs. “Our focus is on the highest value, disruptive innovations and taking them across the ‘valley of death’ with our technology, research and marketing know how” explained Dr. Gemici. Manager of Materials & Chemistry Department Dr. Mustafa Doğu gave additional detail to the CITyFiED group about a range of commercialisation approaches deployed with various partners and institutions to scale and deliver Mir solutions to market or as part of a dedicated industrial assignment. Management shepherd this process with a stage gate approach to reduce project risk and critical ‘go/no-go’ decisions from a Technology Management Board. Dr. Gemici and the team also shared how international project management standards, ISO processes, online workflows and reporting tools all play their role in spin off successes – as well as the numerous intelligent fast failures needed to achieve them. Moving across to the technology laboratory facilities, CITyFiED got hands on experience of the extensive testing facilities. This included a building energy simulation lab able to simulate different out and indoor conditions; testing comfort control and insulation or even simulate a south facing flat using forced air conditioning. A highlight however, was the unique pipe production expertise. “It looks simple, but the mechanical and thermal properties of the piping are very complicated. These are pipes that need to feed water and extract oil at 3000 meters under the sea” Dr Gemici said demonstrating a range of weathering and pressure testing facilities. The group was told how Mir is one of only two companies in the world producing such robust thermoplastic composite pipes with continuous fibre layers, which act as a single piece as opposed to more traditional, multi-layered and steel riser pipe systems. “This makes them lighter, more flexible, easier to service and maintain, non-corrosive – and above all less likely to fracture or fail under internal pressure up to 200 bars (3000 psi) as well as dynamic loads (i.e. ocean waves or earthquakes) which can lead to massive leakages like the Deepwater Horizon oil spill in the Gulf of Mexico disaster” he continued. The laboratory tour continued to give CITyFiED engineers and a group of young researchers from Istanbul Technical University some extra food for thought, especially when visiting the laboratory office spaces, currently a high-tech test chamber and monitoring platform for radiant heating and cooling panels connected to a low Temperature heating and cooling system and heat pump. Mir was keen to put their expertise to use to create a productive and relaxing work environment with exceptional air quality and stable temperatures. Surely something for CITyFiED demonstration site leaders present to consider closely for future works!

Countries

Türkiye