How to prepare SMEs for the uptake of additive manufacturing

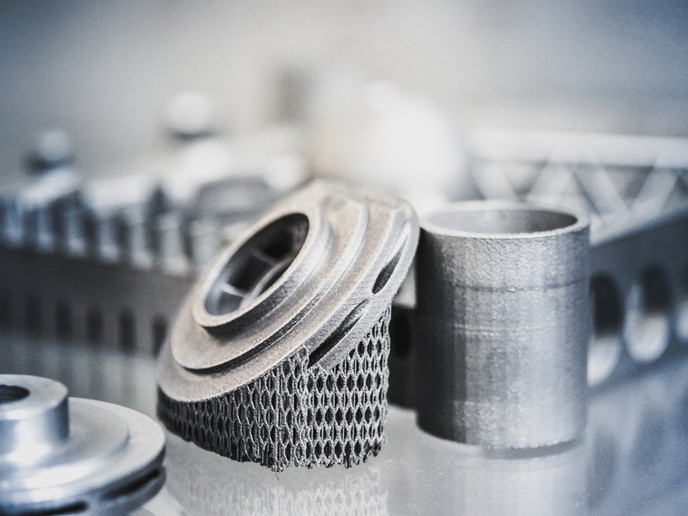

Although it’s a relatively new technology, additive manufacturing (AM) has seen rapid progress in recent years. Thanks to the advancement in this field, 3D-printed parts have already started moving from the R&D phase to production with applications in the aerospace, transport, medical and energy sectors. While larger manufacturers are increasingly benefiting from AM, SMEs are being left behind. Addressing this challenge, the EU-funded AMable project is helping SMEs across all stages to develop ideas towards a final product. It’s also creating a digital framework to provide access to European AM knowledge. AMable has recently opened a new call for proposals to generate innovative ideas for functional products that use AM technologies. Its first open call was launched in 2018. In addition to financial support, the project will offer SMEs opportunities for collaboration, training and experimentation. According to a guide for applicants on the project website, AMable will finance businesses that use 3D printing in experimentation, including short-term feasibility studies and best practice experiments where costs range from EUR 5 000 to 60 000. As noted in the same guide, the project also offers AM-related services through its “services arena” to support experimentation teams so that they could reach a state where their product idea has a design that is additively manufacturable. Selected teams, which will include industrial users and suppliers, will be supported by AMable services and the AMable digital data-chain framework that is based on technologies from the Industrial Data Space and blockchain. Use cases With its first open call, AMable served various cases, including the design and manufacturing of an innovative motorbike fork, the development of a suspension component, the development and production of an optimised hydraulic block, and the development of a vinyl disk cartridge. AM refers to a group of fabrication processes where 3D parts are constructed by adding layers of materials on point, line or planar surfaces. The technology is used to create end-use products in aircraft, dental restorations, medical implants and automobiles. 3D printing is one of the EU’s priority areas of technology. A report by the European Parliament notes that 3D printing could be beneficial for businesses by offering them various advantages. These include decreasing the burden on logistical chains, lessening environmental impact, and reducing storage and transport operations and cost savings related to goods insurance. The ongoing AMable (AdditiveManufacturABLE) project was launched to speed up the adoption of AM technologies by overcoming obstacles related to lack of skilled human resources, access to know-how, equipment, infrastructure and markets. The range of AM support services are provided through an open source and application programming interface-based digital marketplace. AMable also covers “the development of synergies with the already existing I4MS framework, Competence Centres, Digital Innovation Hubs and other related research and innovation activities at the European level,” as summarised on CORDIS. ICT Innovation for Manufacturing SMEs (I4MS) is a European initiative aimed at expanding the digitalisation of manufacturing SMEs. For more information, please see: AMable project website

Countries

Germany