Critical raw materials: Substitution in permanent magnets

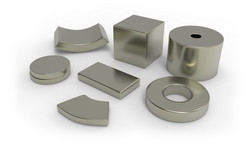

Today we conclude our trio of articles on EU efforts to find substitutes for critical raw materials with a focus on substitution in permanent magnets. At February’s Innovation Network for Substitution of Critical Raw Materials Third Strategic Workshop organised by CRM_INNONET, representatives of three EU-funded projects dedicated to this particular aspect of substitution – VENUS, ROMEO and REFREEPERMAG – presented their activities and objectives. VENUS Dr. Jon Madariaga from Tekniker in Spain, project coordinator of VENUS, kicked off the session on substitution in permanent magnets with a focus on road transport. In recent years, thanks to improved technology, pure electric vehicles (EV) have become a more feasible alternative to cars run on petroleum. However, there are still some considerable challenges to overcome – in particular the fact that the most efficient electric machines use permanent magnets composed by rare-earth materials such as neodymium (light rare earth) and dysprosium (heavy rare earth). 95 % of the global supply of these materials is provided by China, and there is a fear that the country could slash exports again as it did back in 2010. That’s why the VENUS project aims to design electric machines with less permanent-magnet material, with materials different from rare-earths or even completely magnet free. The team has pursued two avenues in parallel – using Switched Reluctance Motors (SRM) or using Permanent Magnet-Assisted Synchronous Reluctance Motor ((PM)SynRM). As Dr Madariaga explained, VENUS is divided into three stages – design, manufacturing and integration in an Azure Ford Transit Connect, followed by test drives. Excellent progress has already been made with regards to design and Dr. Madariaga expects that the team will start fabrication of first prototype by April and then begin integration in the vehicle. ROMEO The ROMEO project, presented by project coordinator Prof. Dr. Spomenka Kobe from the Jožef Stefan Institute in Slovenia, is focused on drastically decreasing the amount of heavy rare earth needed in permanent magnets for the renewable energy sector and totally substituting rare earth permanent magnets with new magnetic materials. Motors for electric vehicles and the generators in wind turbines, for example, require strong highly coercive magnets to operate at temperatures well over 100 degrees and to withstand high demagnetizing reverse field. Like the magnets currently used in EVs, these magnets are based on the rare earth elements neodymium and dysprosium. As Prof. Dr. Spomenka Kobe explained, ROMEO started out with two main goals – the first was to develop several novel microstructural-engineering strategies that will dramatically improve the properties of magnets (especially the coercivity) based on a composition with a drastic reduction in heavy rare earth materials or purely based on light rare earths elements; and the second was to develop a totally rare-earth-free magnet. Although the project is not due for completion until the end of this year, the first of these goals, which will enable magnets to be used at temperatures above 100 degrees, has already been achieved. The exploitation of ROMEO’s results will now take place in two phases: idea to prototype, and prototype to market. REFREEPERMAG Closing off the session on permanent magnets, project coordinator of REFREEPERMAG, Dr. Dimitris Niarchos from the National Centre of Scientific Research DEMOKRITOS in Greece, explained how the project is the first to pursue a combinatorial approach to developing rare earth free permanent magnets. The innovative aspects of the project, Dr. Niarchos explained, are the combinatorial modelling of iron-cobalt based alloys (which are abundant and inexpensive); combinatorial synthesis and characterization and novel compaction techniques for sintered magnets. The project team has followed four separate paths in the pursuit of developing rare earth free permanent magnets, and its work has already been recognised with the award for ‘Best on-going Project’ in Industrial and Materials Technologies in the FP7. Ultimately Dr. Niarchos hopes that the project will result in the sustainable, long-lasting substitution of supply-critical materials needed for innovations in the high-technology sectors of European industries. By providing a reliable substitution, the project will contribute towards free rare earth resources for devices in display and microsensor technologies where substitution is not an option as well as driving down the cost of rare earth raw materials.

Countries

Greece, Spain, Slovenia